In today's fiercely competitive industrial market, industrial product packaging is no longer just a "protective shell" for products. It plays an increasingly critical role in brand building, product differentiation, and meeting personalized customer needs. With the shift of industrial production mode towards small batch, multi variety, and customization, the limitations of traditional packaging printing methods are becoming increasingly prominent.

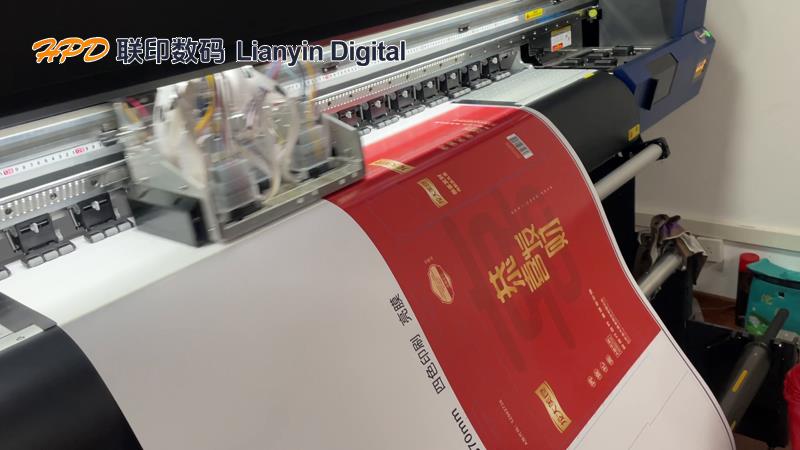

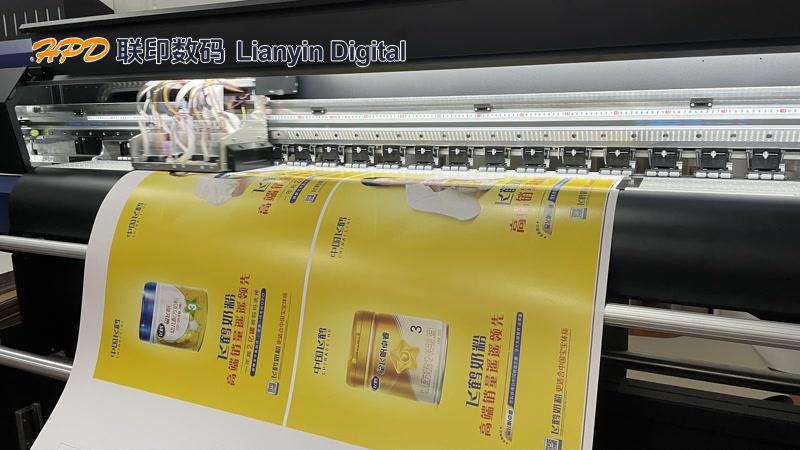

Digital printers, with a series of significant advantages, are gradually becoming the new favorite in the field of industrial product packaging. Among them, the small batch digital printing machines launched by Lianyin Digital, combined with water based polymer carbon ink solutions, have brought a new solution for the rapid production of small batch industrial product packaging and individual orders.

The cost-effectiveness has significantly improved

In traditional packaging printing, the plate making process is costly and time-consuming. For small batch orders commonly found in industrial packaging, the cost of plate making is allocated to each product, resulting in a significant increase in packaging costs. Lianyin Digital's small batch digital printing machine and water based polymer carbon ink enable efficient printing without plate making,this digital box printer solution quick drying of images, and no need for high-power additional heaters. Reducing electricity consumption further lowers costs. Moreover, the equipment maintenance is simple, reducing labor costs and downtime, and the overall cost advantage is significant.

Efficient production meets fast-paced demands

Industrial production emphasizes efficiency, especially when facing urgent orders or seasonal demand fluctuations.Digital printers have fast printing speeds and can achieve high-speed continuous printing. Moreover, when switching between different packaging designs, only the files need to be changed on the computer, without the need for complex mechanical adjustments or re plate making, greatly reducing production preparation time. This efficient production mode enables enterprises to quickly respond to market demand, deliver products in a timely manner, and improve customer satisfaction.

Excellent personalized customization capability

Nowadays, industrial customers have increasingly high demands for personalized packaging, hoping to stand out among numerous competitors through unique packaging. Inkjet digital printing technology can present complex brand logos, exquisite patterns, and variable data containing product parameters clearly and accurately on the packaging surface. Carbon polymer ink has excellent color expression and can restore rich color layers, making the visual effect of packaging more outstanding. Enterprises can quickly customize exclusive packaging according to the needs of different customers, endowing products with unique brand charm and enhancing market competitiveness.

Environmental advantages are prominent

Today, with increasing environmental awareness, the packaging industry is also facing pressure for green transformation. The water based polymer carbon ink solution of Lianyin Digital adopts an environmentally friendly ink formula and a water-soluble ink solution, which conforms to the concept of environmental protection. It does not produce harmful gases during the printing process and meets strict environmental standards. At the same time, the precise printing technology of the device avoids ink waste and reduces the negative impact on the environment. For industrial enterprises that focus on sustainable development and pursue a green image, Lianyin Digital's solution is undoubtedly an ideal choice for achieving environmentally friendly packaging. Small batch packaging printers, with outstanding advantages in cost control, production efficiency, personalized customization, and environmental protection, provide efficient and high-quality solutions for small batch industrial product packaging and rapid production of individual and short orders. It not only solves the pain points of traditional packaging printing, but also gives industrial enterprises an advantage in fierce market competition, promoting the industrial packaging industry to move towards a new stage of development.