In the modern commodity circulation system, corrugated cardboard boxes are the most important form of product packaging, carrying important functions of protecting goods, transmitting information, and enhancing brand image. According to statistics, the annual consumption of corrugated cardboard boxes worldwide is in the billions, and the huge market demand is driving continuous innovation in cardboard printing technology.

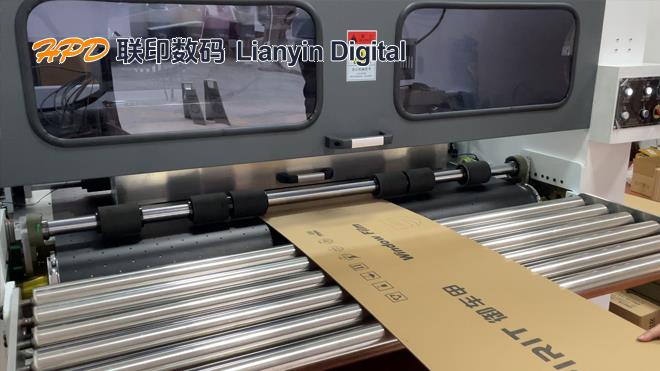

From traditional printing machines to cardboard box printing machine, the industry is undergoing a profound transformation, which not only reshapes production models but also brings new opportunities and challenges to the packaging printing field. Compared with traditional printing machines, cardboard digital printers can be regarded as "disruptors" in the field of packaging printing.

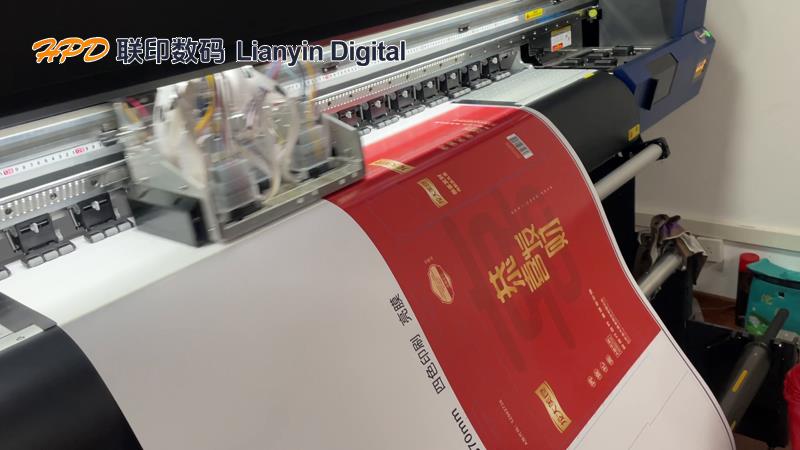

Traditional printing machines need to go through a tedious plate making process before production, which not only consumes time and cost, but also requires re plate making once design modifications occur, resulting in extremely low efficiency. The digital printing machine for corrugated cardboard boxes, with its core advantage of "no plate printing", has completely freed itself from the constraints of plate making. Designers only need to transfer electronic files to the printer to achieve instant printing. Whether it is small batch customization or personalized orders, they can be completed in a short period of time, greatly shortening the delivery cycle. For industries such as e-commerce and cultural and creative industries that require high timeliness, this "lightning fast" printing and delivery capability is undoubtedly a weapon to seize market opportunities.

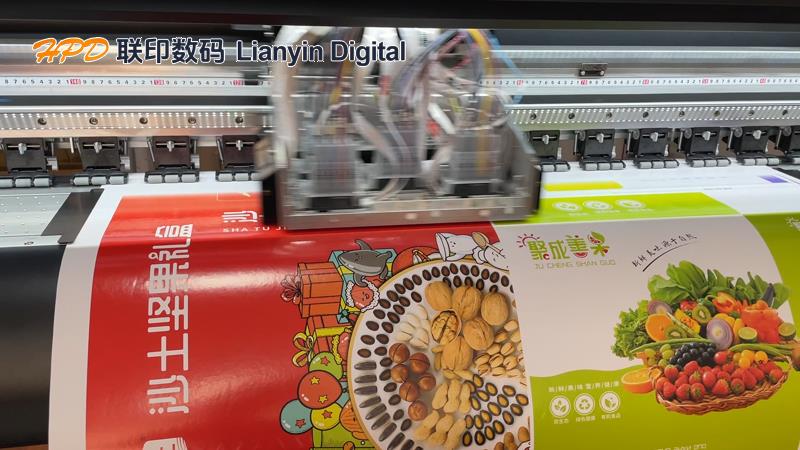

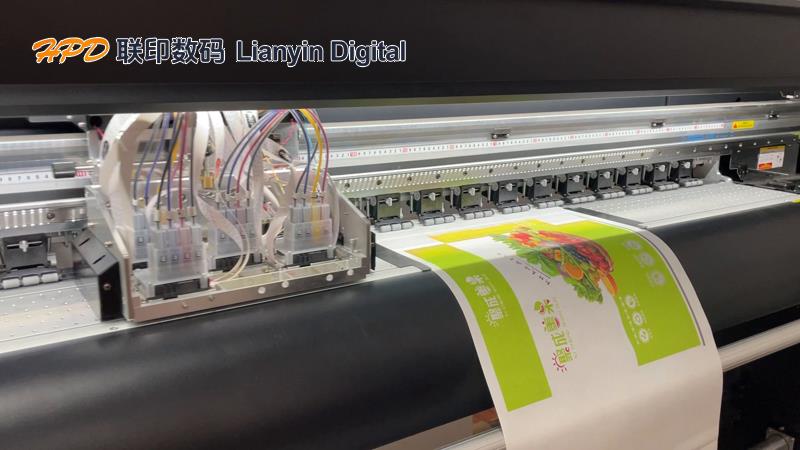

In terms of customized production, digital paper box printers have demonstrated unparalleled advantages. With the increasing diversification of the consumer market, customers have endless personalized demands for cardboard box sizes, patterns, text, and more. Traditional printing machines are limited by fixed patterns and specifications, making it difficult to meet complex and ever-changing customization needs, while digital printing machines for cardboard boxes can easily cope. The high-speed corrugated box digital printing machine of Lianyin Digital can expand the printing width to 2.5 meters or even wider by flexibly increasing the number of nozzles according to customer needs. Even ultra large industrial packaging boxes can achieve precise printing. At the same time, digital printing technology supports high-resolution image output, which can perfectly present delicate gradient colors or complex brand logos, providing strong technical support for the shaping of brand image.

However, the development of technology has always been a double-edged sword, and the flatbox printer is no exception. Despite its outstanding performance in personalization, flexibility, and other aspects, its slow printing speed has also become a bottleneck restricting its large-scale application. This speed disadvantage is particularly evident when facing large quantities of standardized orders. However, industry experts point out that with the continuous upgrading of nozzle technology and optimization of ink transfer systems, the printing speed of digital printers is gradually improving.

In addition, some digital print heads are not suitable for printing full color block images for a long time, which also brings limitations in application. And small-scale cardboard box printing machines also face certain challenges in cost control, color management, and other aspects. For example, the cost of specialized ink used in digital printing is relatively high, and equipment maintenance costs are also relatively expensive, which to some extent drives up production costs. In addition, the issue of color consistency in different batches of printing is also a major challenge that troubles the industry. To address these issues, companies are reducing consumable costs through technological innovation and introducing advanced color management systems to ensure stable printing quality through precise color calibration and control.

Looking ahead to the future, with the deep integration of emerging technologies such as 5G and artificial intelligence, digital printing technology for cardboard boxes is expected to see even greater breakthroughs. The intelligent printing control system will achieve automatic adjustment and optimization of equipment, further improving printing efficiency and quality; The research and application of environmentally friendly ink will make digital printing more in line with the development trend of green packaging. It can be foreseen that, driven by the continuous growth of personalized demand and the acceleration of intelligent manufacturing, digital printer for corrugated boxes will occupy an increasingly important position in the field of packaging printing, becoming the core force driving the high-quality development of the industry.