Against the backdrop of consumer upgrading and increasing demand for personalization, the color box packaging industry is undergoing a silent and profound transformation. The traditional large-scale and standardized production mode is gradually being replaced by small-scale and customized demand. This trend not only changes the market landscape, but also creates an urgent demand for efficient and flexible production tools. In this context, small batch digital printing machines and digital printing technology, with their unique advantages, have become a key force driving industry transformation, especially demonstrating disruptive value in the field of small batch individual orders.

1. In recent years, with the rapid development of e-commerce, cultural and creative industries, fast-moving consumer goods and other industries, packaging demand has shown the characteristics of "short cycle, multiple varieties, and small batch". For example, a new product launch may only require a few hundred customized packages, while traditional printing processes are difficult to meet this flexible demand due to high plate making costs and long delivery cycles. At the same time, the demand for fast trial and error and low-cost trial production has surged among entrepreneurs, designer studios, and small and medium-sized enterprises. Traditional printing factories are also facing pain points of low efficiency and high costs in pre press sampling. Data shows that the global small batch packaging market has an annual growth rate of over 12%, with China, as a major manufacturing country, showing a more significant trend. How to achieve efficient and low-cost production while ensuring quality has become the core proposition for industry breakthroughs.

2. Digital Printing Technology: Breakers in Small Batch Production

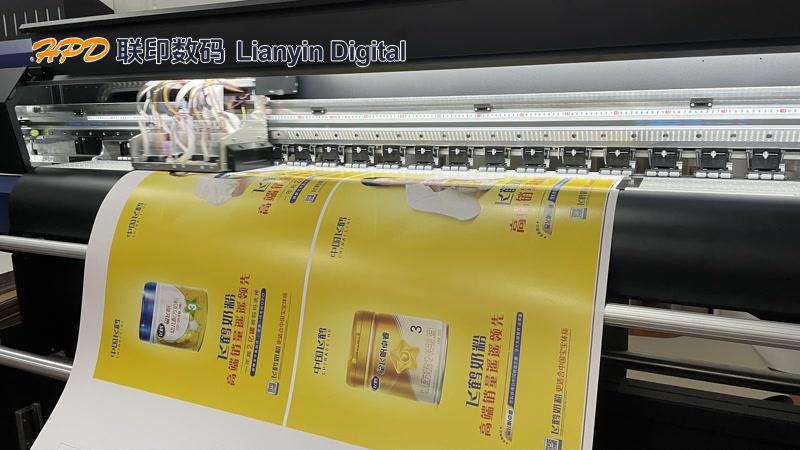

Digital printing technology provides a new solution for small batch production by directly converting digital files into physical products, bypassing the traditional printing plate making process.

. Its core advantages are reflected in the following three aspects:

Rapid prototyping, shortening the research and development cycle

Digital printers can complete sample output in a few minutes, supporting complex patterns, gradient colors, and personalized designs, helping entrepreneurs quickly validate their ideas and reduce trial and error costs.

. For example, a certain cultural and creative brand successfully shortened its product launch time by completing packaging design and sampling within 24 hours through digital printing.

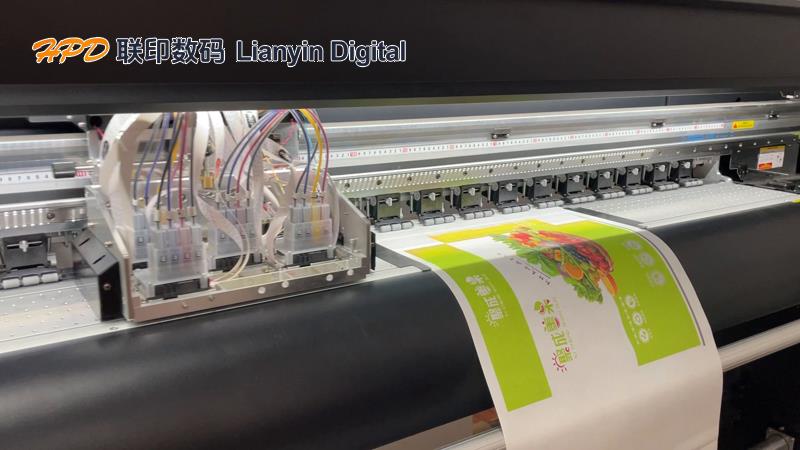

On demand production reduces inventory pressure

Traditional printing requires advance stocking, while digital printing can achieve "production to order" and avoid excess inventory.

. For small batch orders, the cost per piece of paper is only 1/5-1/3 of traditional printing, especially suitable for customized and limited edition products.

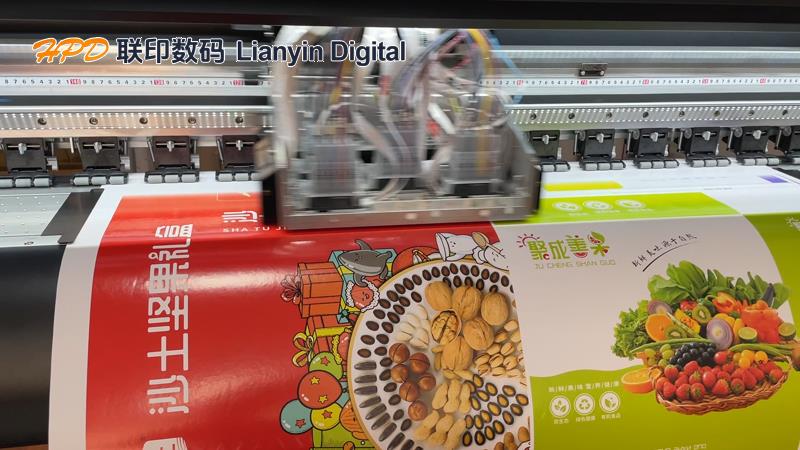

Flexible adaptation, compatible with diverse needs

Digital printing supports multiple materials (such as paper, metal foil, PET film) and processes (such as UV, hot stamping, local polishing), which can meet the refined requirements of high-end packaging.

. Meanwhile, its feature of not requiring plate making makes the marginal cost of small batch orders approach zero. Thirdly, empowering diverse scenarios: from entrepreneurial teams to traditional printing factories. The popularization of digital printing technology is creating new value for different types of market entities: Entrepreneurs and studios. For startups or independent designers, digital printing has lowered the entry barrier. High quality packaging design can be achieved without expensive plate making costs, helping brands quickly establish a differentiated image. For example, a handmade brand produced limited edition gift boxes through digital printing, resulting in a 300% increase in monthly sales.

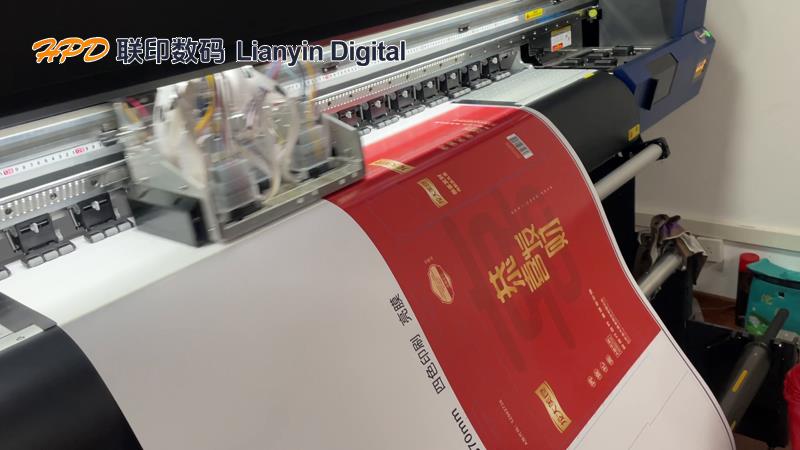

Transformation and upgrading of traditional printing factories

Faced with the impact of small batch orders, traditional printing factories can build a composite model of "traditional printing+digital proofing" by introducing digital printing equipment. The use of digital machines for rapid prototyping during the prepress stage not only improves customer communication efficiency, but also saves time for subsequent large-scale production. Through this strategy, a large packaging company has reduced the sampling cycle from 3 days to 2 hours, resulting in a significant improvement in customer satisfaction. Cross industry application expansion: Digital printing technology has also extended to personalized packaging scenarios in fields such as healthcare, food, and electronic products. For example, drug packaging can be customized with anti-counterfeiting labels through digital printing, and electronic product gift boxes can incorporate dynamic QR code design to enhance user experience.

4. Future prospects: Technological iteration and ecological synergy. With the continuous advancement of technologies such as inkjet and laser, the accuracy, speed, and environmental performance of digital printing continue to improve. For example, the new generation of environmentally friendly digital printers has achieved the replacement of solvent based ink with water-based ink, which is in line with the trend of green packaging. In addition, the integration of digital management systems makes functions such as order tracking and remote debugging more intelligent. In the future, digital printing may be deeply integrated with technologies such as AI design and blockchain traceability, forming a new industrial chain of "intelligent customization+precision production".

For practitioners, seizing this technological dividend is not only an inevitable choice to cope with market changes, but also the key to seizing the future competitive high ground. In today's era where small batches and personalization have become mainstream, digital printing technology is redefining the value chain of color box packaging with the characteristic of "flexible production". It is not only a tool for entrepreneurs and a replacement for traditional enterprises, but also a catalyst for the entire industry to move towards intelligent manufacturing. When efficiency and creativity are no longer in opposition, and when cost and quality can be balanced, the rise of digital printing may be the starting point for the packaging industry to move towards high-quality development.