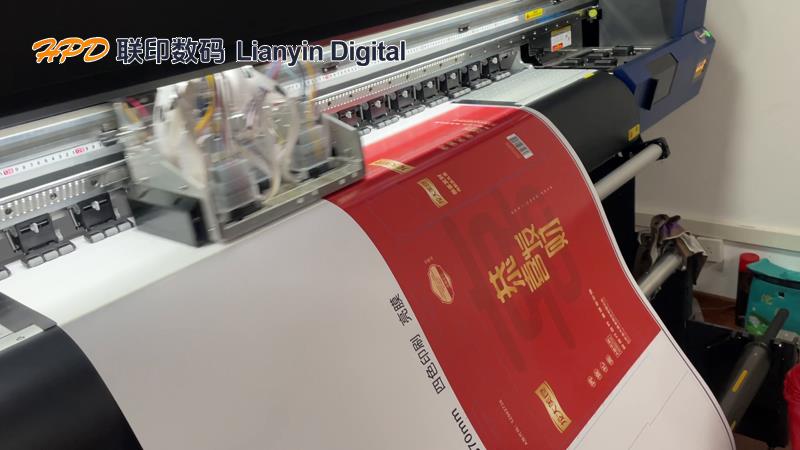

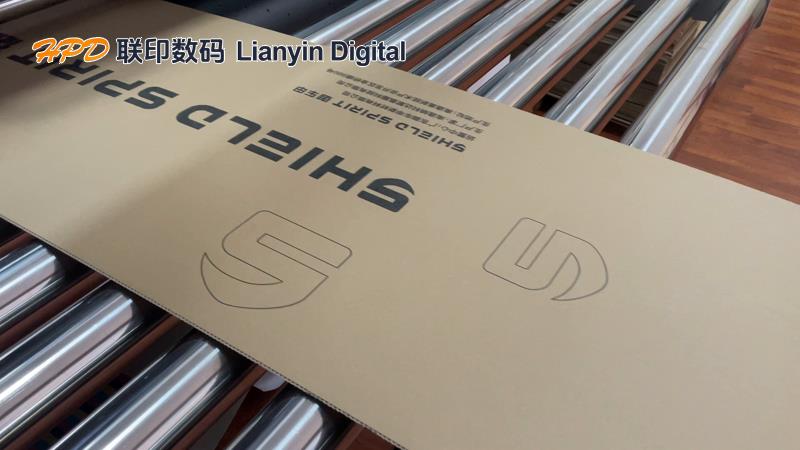

Packaging color box digital printing machine

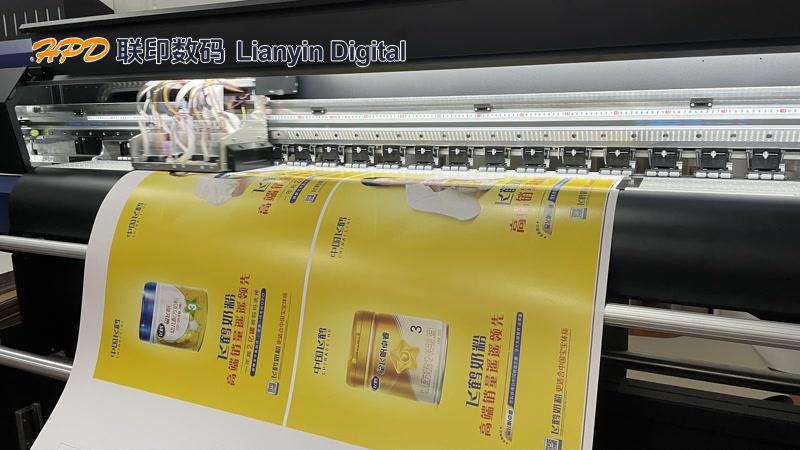

Digital printing has a broad prospect for small batch packaging. It can meet the personalized needs of consumers, quickly print finished products with digital printing to respond to market changes, assist in new product launches and promotions, achieve on-demand production, reduce inventory costs, and avoid resource waste. In the field of e-commerce, adapting to small batch and multi variety order models, enhancing product competitiveness through exquisite packaging. It can be said that digital packaging printing production has great potential for development. Choosing a cost-effective small batch packaging digital printing machine requires consideration of the following key aspects:

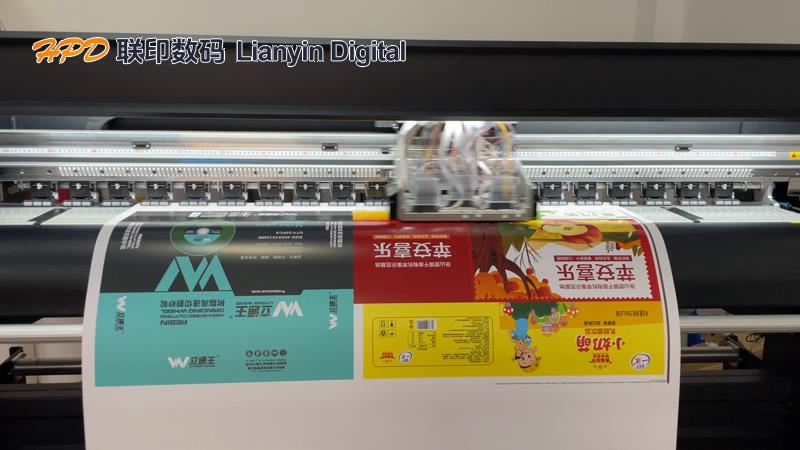

1. Printing requirement matching: Clearly identify the main packaging types for printing, such as cardboard boxes, labels, flexible packaging, etc. Different types have different functional and characteristic requirements for the printing machine. For example, cardboard printing may require a larger printing format and a certain substrate thickness support; Label printing requires high precision and alignment. At the same time, the complexity and color requirements of the printed content should also be considered. If it is simple text and lines, the resolution requirements for the printing machine are relatively low; For exquisite color patterns, high-resolution and color rendering equipment is required.

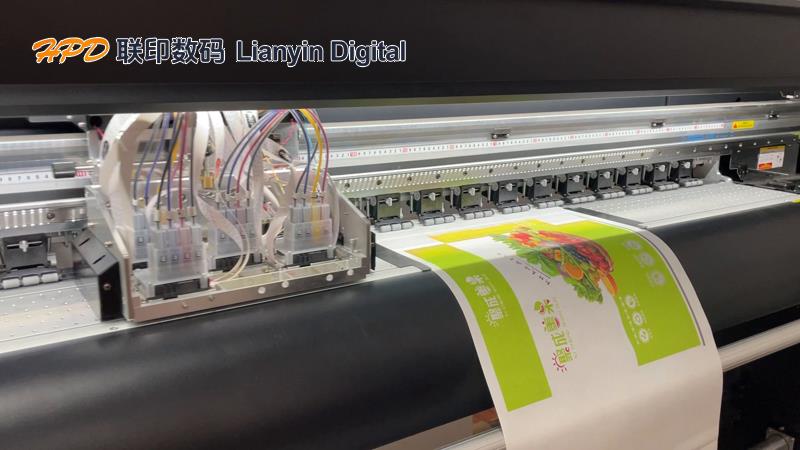

2. Equipment performance considerations: The printing resolution should be high enough, generally at least 600 × 600dpi. For high-quality packaging, 1200dpi or higher is better to ensure clear text and delicate images. In terms of printing speed, according to the expected production efficiency requirements, for small batch color box digital printing, the number of different print heads affects the printing speed. The most widely used domestically produced models on the market are those made with Epson nozzles. These scanning digital printing machines typically produce tens to hundreds of cubic meters per hour. Direct jet digital printers, on the other hand, are faster at several tens of meters per minute and are typically used for printing corrugated cardboard. The nozzle technology is also crucial, commonly including piezoelectric and hot air bubble nozzles. Piezoelectric nozzles have high precision and long lifespan, but high cost; The cost of thermal foaming nozzles is low, but their accuracy and lifespan are slightly inferior. In addition, the number and arrangement of nozzles can affect printing speed and quality.

Small batch corrugated cardboard digital printing machine

3. Media compatibility: Ensure that the printing machine can adapt to various packaging materials, such as paper (including corrugated paper, cardboard, copperplate paper, etc.), plastic film, label materials, metal foil, etc. Some high-end devices can also support special media such as transparent film, adhesive stickers, etc.

4. Cost analysis: The purchase cost should be within the budget range. Generally, digital printing machines with fewer print heads have relatively lower prices and are suitable for small businesses or small batch printing. If larger production capacity is needed, customized small batch printers can be used. At the same time, it is also necessary to consider whether the purchasing channels for digital printing machine ink consumables are convenient and whether the prices are stable. In terms of maintenance costs, understand the maintenance requirements and expenses of the equipment, including the fees for regularly replaced parts and repair services. Some devices are easy to maintain and users can maintain them themselves; High end models may require professional technical personnel for maintenance, which incurs higher costs.

5. Brand and after-sales service: Famous brands have more guaranteed product quality, performance, and after-sales service. Understand the brand's after-sales service network coverage, response time, repair methods, and whether it provides on-site service, warranty period, etc. Good after-sales service can promptly solve problems during use, reduce downtime and losses.