In today's increasingly competitive printing industry market, cost control has become the key for printing enterprises to enhance competitiveness and achieve sustainable development. Digital printing machines, with their advanced technology and unique production mode, have brought new cost control ideas and methods to printing enterprises, becoming the core engine for reducing costs and increasing efficiency.

From the preliminary preparation stage, digital printing machines can significantly reduce costs. Traditional printing requires a plate making process before printing, which not only consumes a lot of time and manpower, but also requires high investment in plate making materials, equipment, and related processes. For example, the cost of a regular printing plate can be as high as hundreds or even thousands of yuan. For enterprises that need to frequently replace printed content, plate making costs are a heavy burden. Digital printing does not require plate making and can be printed directly through digital files, which completely eliminates all the costs incurred in the plate making process. Enterprises only need to import the designed electronic documents into digital printing machines to start printing immediately, which not only saves plate making costs but also shortens preparation time, enabling enterprises to quickly respond to customer needs and seize more business opportunities.

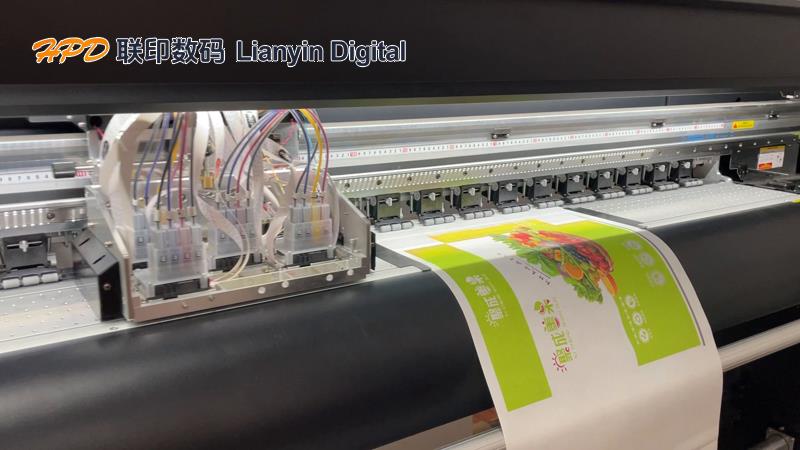

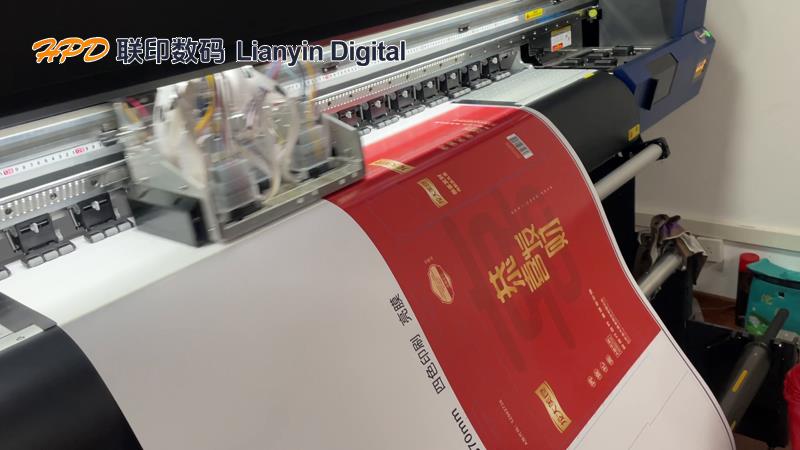

In the production process, the precise control of digital printing machines effectively reduces the cost of consumables. Traditional printing is difficult to achieve precise control over ink usage, and ink waste is prone to occur during the printing process, especially when printing complex colors and diverse patterns. Ink consumption is high and difficult to recycle. Digital printing machines adopt advanced nozzle technology and precise ink droplet control technology, which can accurately allocate ink usage according to the needs of printing content, minimizing ink waste. In addition, the paper utilization rate of digital printing is also higher. It can flexibly adjust the printing layout to avoid wasting paper edges and corners caused by fixed layout sizes. Compared with traditional printing, it can save 10% -15% of paper costs.

For small-scale printing businesses, the cost advantage of digital printing machines is particularly prominent. Traditional printing is limited by the minimum printing volume, and for a small number of printing orders, the unit printing cost is often high due to the high allocation of fixed costs. Digital printing does not have a limit on the minimum printing quantity, and can be produced with the same cost structure for a single sheet.

In terms of inventory management, digital printing machines have also saved businesses a lot of costs. Under the traditional printing mode, enterprises often need to print a large number of finished products in advance for inventory in order to meet market demand. This not only occupies a lot of storage space and increases storage management costs, but also faces the risk of product backlog, expiration and scrapping due to changes in market demand.

Small batch digital printing machine supporting on-demand printing, enterprises can produce according to actual order conditions, achieving zero inventory or low inventory management. This flexible production method allows enterprises to avoid the capital occupation cost and warehousing risk caused by inventory backlog, and better invest funds into the core business and technological research and development of the enterprise.

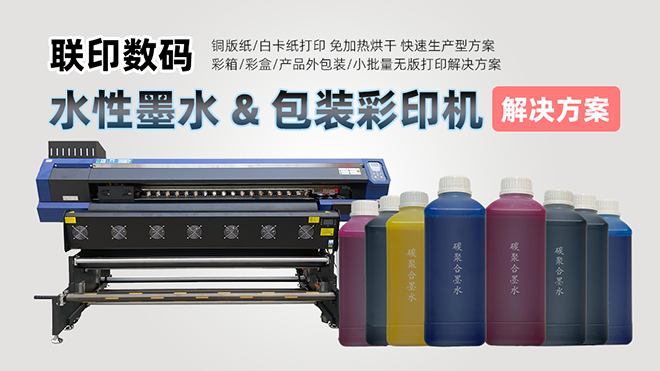

Guangzhou Lianyin Digital Technology Co., Ltd. provides customers with Packaging Box Digital Printer. Overall solution for small batch packaging printing. This solution integrates our company's environmentally friendly water based polymer carbon pigment ink and plateless digital printing machine .For rapid production of oversized color box packaging printing, color box/gift box/wine box/paper box printing, product outer packaging color printing, etc.

Digital printing machines have comprehensively reduced the operating costs of printing enterprises by eliminating the plate making process, accurately controlling consumables, adapting to small batch printing, and optimizing inventory management. In the wave of digital transformation, the reasonable introduction of small batch digital printers by printing enterprises will occupy a more advantageous position in cost control and market competition.