In the field of packaging printing, packaging color boxes and color boxes, as important "outerwear" of products, have always been highly concerned about their printing quality, design effect, and production efficiency. Traditional printing methods, such as offset printing and flexographic printing, have gradually revealed some drawbacks in the face of today's diverse, personalized, and rapidly changing market demands, such as long plate making cycles, high costs, and poor flexibility. The emergence of printless digital printing machines for packaging color boxes has brought new opportunities for packaging printing.

Application advantages of digital printing machines in packaging color boxes

Meeting personalized customization needs

In today's consumer market, consumers' pursuit of product personalization is becoming increasingly strong, which also extends to the packaging field.

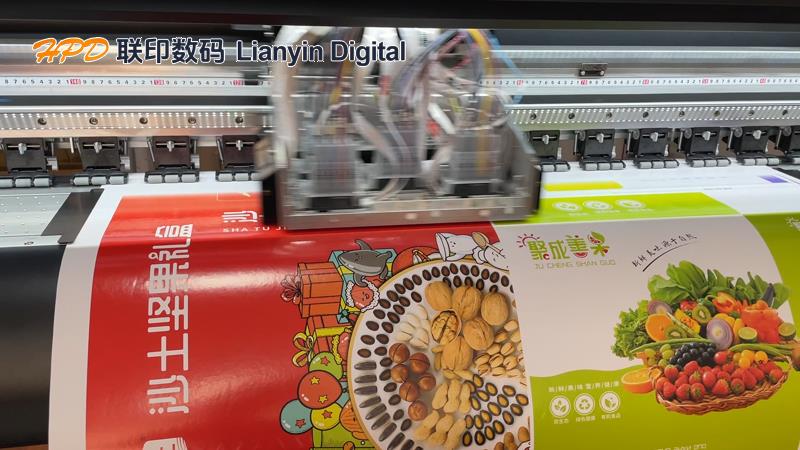

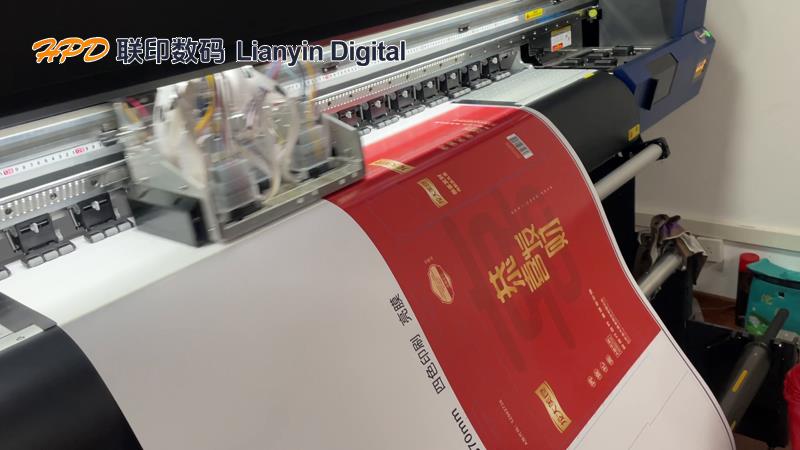

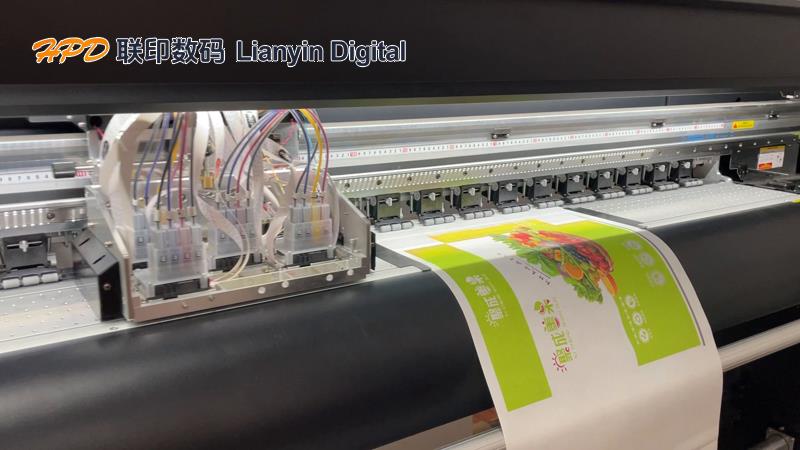

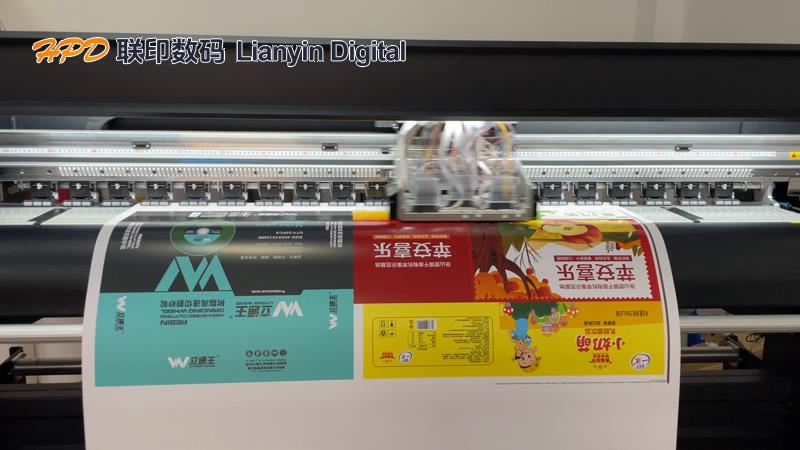

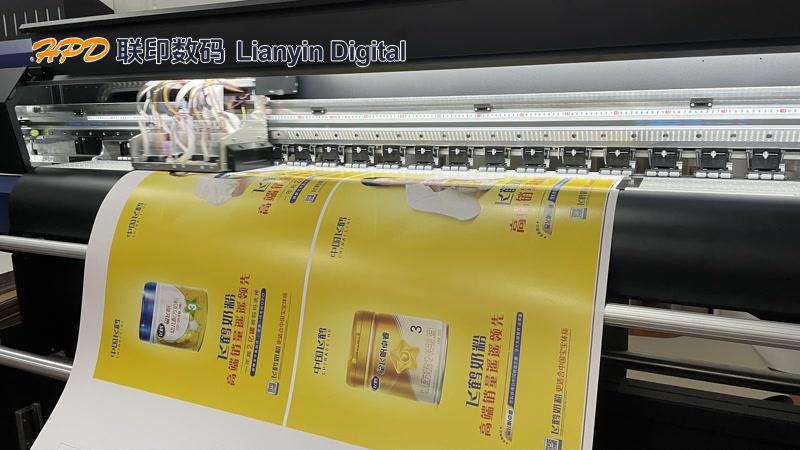

. Brand owners need to attract consumers' attention and highlight product differentiation through unique packaging design. Inkjet digital printers can easily achieve fast printing of small batches and multiple varieties. For packaging color boxes and color boxes, whether it is exquisite patterns, unique text, or complex QR codes and barcodes, they can be accurately presented. For new product launches, limited edition products, personalized customization, and other needs, individual digital printers can print from one sheet, allowing brand owners to quickly transform their ideas into actual products and stand out in fierce market competition.

Shorten production cycle

In traditional printing technology, the plate making process often consumes a lot of time, from the design draft to the final plate making completion, which may take several days or even longer.. The digital method uses digital image information transmission to directly transfer design files to the print head for printing, without the need for plate making process. From receiving new design requirements to completing printing, it can be completed in just a few hours, greatly shortening the entire production cycle and reducing the cost of small batch orders. For traditional printing, plate making costs account for a relatively large proportion of the total cost, so the cost of small batch orders is relatively high. Digital printing does not require plate making, avoiding the expenditure of plate making costs. For small batch orders of packaging color boxes , such as printing hundreds of color boxes or a small number of special specification color boxes, it can significantly reduce costs.

The environmental advantages are obvious

With the continuous enhancement of environmental awareness, the environmental requirements of the printing industry are also increasing.. In the packaging and printing process of digital printing machines, water-based ink is mostly used. Compared with solvent based ink used in traditional printing, water-based ink has the characteristic of low volatile organic compound (VOC) emissions, which poses less harm to the environment and human health.

Of course, there are also some limitations to packaging color box digital printers.

The equipment cost is relatively high.

Especially for devices with high-precision and high-speed printing capabilities, which can be sold for millions or even tens of millions of yuan. For many small packaging and printing companies, this is a huge investment that exceeds their financial capacity. In addition to the procurement cost of equipment, it is also necessary to consider the investment in supporting equipment, such as professional color management systems, high-quality paper feeding devices, etc., which increase the initial investment pressure of enterprises.

The maintenance and replacement cost of the nozzle is high.

The nozzle is the core component, and its accuracy and stability directly affect the printing quality. However, the maintenance requirements for the nozzle are high. Due to the extremely fine nozzle of the nozzle, it is easily affected by ink impurities, dust, and environmental factors during use, resulting in problems such as blockage and wear. Once the nozzle malfunctions, maintenance and replacement costs are high. A regular high-precision nozzle may cost thousands of yuan, while some high-end nozzles are even more expensive.

Ink cost and compatibility issues

Different inkjet technologies, paper types, and machine types require the use of different inks. In practical applications, there may be issues with ink compatibility. For example, when printing on rough corrugated paper, ink may not adhere well, resulting in poor printing results and affecting product quality.

Printing size and shape restrictions

Some machines have certain limitations on printing size, which may not meet the printing needs of some large color boxes or special packaging color boxes. The fixed position design of the digital printing machine's nozzle makes it difficult to achieve comprehensive and uniform printing for packaging with special shapes, high drop or irregular surfaces.

Driven by the development of e-commerce and logistics industries, technological innovation, and sustainable development needs, the digital pringing application prospects are broad. Of course, its application also faces limitations such as high equipment costs, high nozzle maintenance and replacement costs, ink costs and compatibility issues, as well as printing size and shape limitations. In order to better promote the application of packaging color boxes and color box fields, it is necessary for packaging printing enterprises, digital printing machine manufacturers, and relevant scientific research institutions to work together. Overcome its limitations and promote the development of packaging color boxes and color box printing industry towards higher quality, efficiency, and environmental protection.