In the packaging printing industry, market demand is increasingly diversifying and personalizing. There is a growing number of orders for small-batch color boxes and cartons, making digital printing machines a focal point in the sector. So, what is the suitable order volume for small-batch color box digital printing machines, and what are their diverse application scenarios and cost performances?

I. Suitable Order Volume

Small-batch packaging digital printing machines excel in medium to small batch orders, particularly in ultra-small batches. With traditional printing methods, small orders incur high plate-making costs, while digital printing eliminates this expense due to its plateless nature.

- Orders below 100 pieces: The absence of plate-making results in cost advantages, making it suitable for new product sampling and customized trial production.

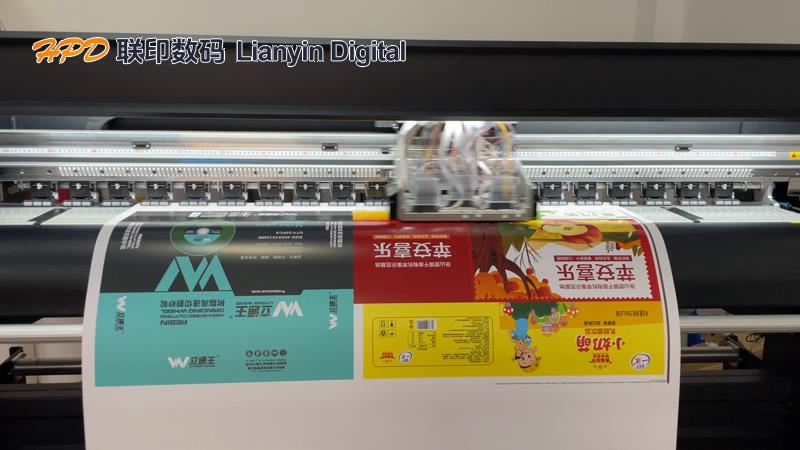

- Orders between 100-500 pieces: Variable data printing (such as numbering or custom graphics) and rapid job changeover increase efficiency, reducing delivery cycles to half of traditional printing time or less.

- Orders above 500 pieces: Traditional printing's economies of scale become apparent, but digital printing can optimize cost structures through hybrid production models (digital plus offset printing).

II. Application Scenarios

(A) E-commerce and New Retail Sector

E-commerce and new retail heavily rely on personalized packaging and quick responsiveness. Digital printing's "print-on-demand" feature enables swift production of holiday promotional gift boxes, DTC brand custom packaging, etc. Brands can test market feedback with small batch samples before new product launches, avoiding inventory risks associated with traditional bulk production.

(B) High-end Consumer Goods Industry

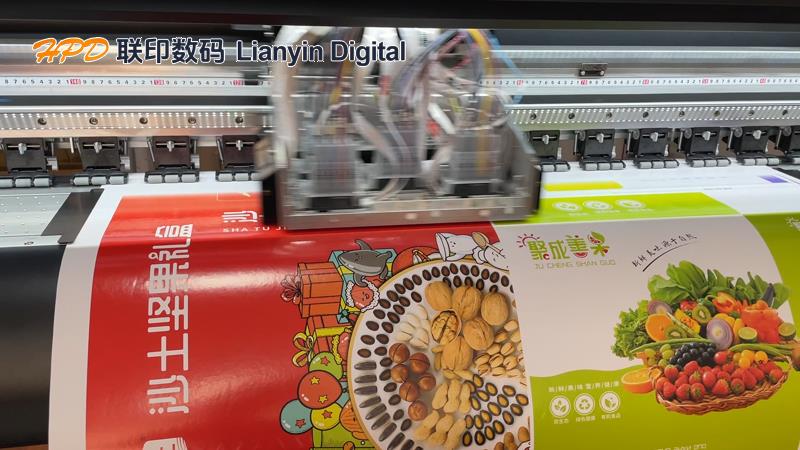

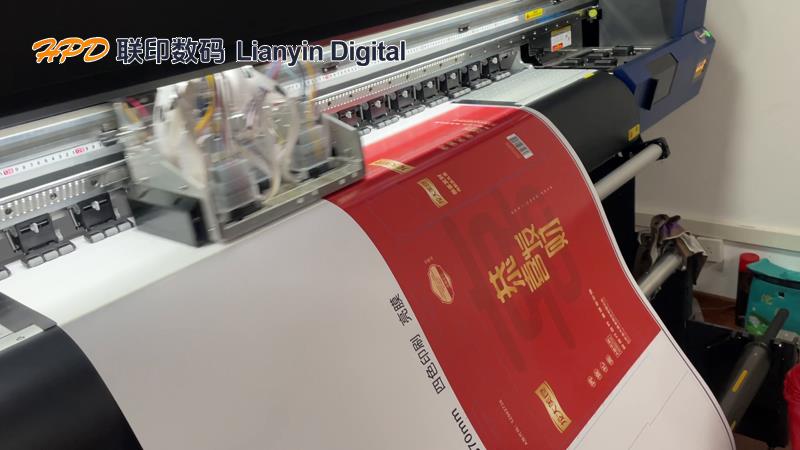

In the high-end consumer goods sector, packaging represents brand value. Digital printing, with technologies like UV inkjet, can achieve embossing, hot foil stamping, and other special effects, enhancing packaging quality. For instance, an international beauty brand used digital printing for multiple small batches of seasonal limited edition packaging, precisely aligning with a "scarcity" marketing strategy.

(C) Fast-moving Consumer Goods and Promotional Events

Fast-moving consumer goods (FMCG) promotions are frequent, creating a demand for short-term promotional packaging. Digital printing can promptly produce regional marketing packaging, holiday-themed packaging, such as a beverage brand's region-specific special packaging, adapting swiftly to regional consumer preferences.

(D) Industrial and Logistics Phases

In industrial sectors, components packaging (like anti-static packaging for electronics or sterile packaging for medical devices) often requires small batch customization. Digital printing machines can integrate traceability systems to enhance management efficiency. In logistics, zero-inventory, on-demand production of variable data labels avoids waste from traditional printing inventory.

III. Cost Analysis

(A) Equipment Cost

Pricing for packaging digital printers varies based on models:

- Entry-level models: Suited for small packaging factories, priced from tens of thousands to hundreds of thousands, fulfilling daily small to medium batch production needs.

- Middle-to-high-end models: Offering high-speed printing capabilities, suitable for large-scale production scenarios, with higher initial investments but significant productivity improvements.

- Domestic models: Provide excellent value for money, particularly excelling in corrugated cardboard printing, making them an ideal choice for small to medium-sized packaging plants.

(B) Consumables and Operational Costs

- Ink cost: Using eco-friendly inks, the overall cost is comparable to traditional printing, with reduced chemical consumption due to no plate-making process.

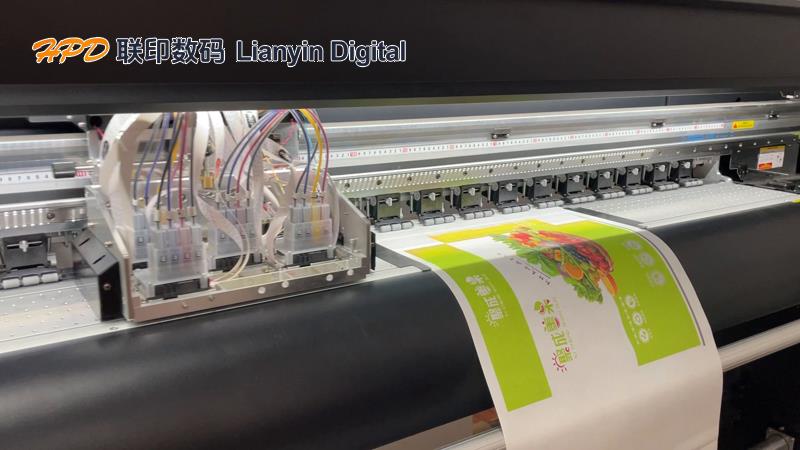

- Labor cost: Simplified operation requires only 1-2 operators, significantly lowering labor costs compared to traditional printing.

IV. Equipment Advantages

The core strengths of small-batch color box and carton digital printing machines lie in:

- Flexibility: Rapidly switch printing content and designs to accommodate diverse order requirements.

- Sustainability: Plateless process reduces chemical pollution, aligning with green printing trends.

- Quality: High-precision printing technology ensures fine pattern reproduction and rich effects, boosting packaging visual appeal.

Small-batch color box and carton digital printing machines, with their flexibility, efficiency, and eco-friendliness, provide an ideal packaging solution for industries like e-commerce, high-end consumer goods, and FMCG. In the trend of "small orders and fast response," digital printing machines not only upgrade production tools but also serve as a crucial competitive edge for businesses adapting to market changes.