In the current era of personalized consumer demand and intense market competition, the demand for small batch packaging has surged. Digital printing technology, with its advantages of efficient production, flexible customization, cost reduction and efficiency improvement, has become the new favorite of the industry. It is expected that by 2029, the global digital inkjet printing market for packaging and labeling will reach $18.08 billion and $10.79 billion, respectively. Under this trend, selecting suitable digital printing machine equipment can be considered from the following core dimensions.

Clarify printing requirements

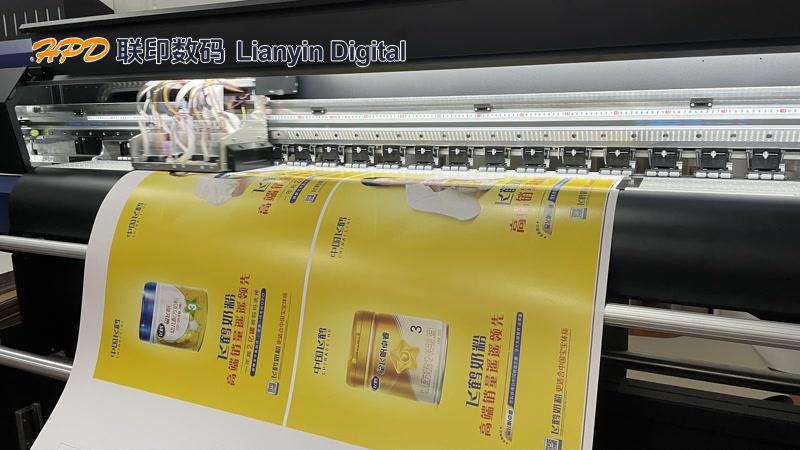

The packaging type determines the basic adaptability of the equipment. Printing on corrugated cardboard boxes requires equipment to support printing with large substrate thickness and width; Label printing has strict requirements for accuracy and registration; Flexible packaging such as plastic film requires ink with excellent adhesion and drying speed. In addition, the complexity of printed content also affects device selection. Simple text lines have low resolution requirements, while tempting patterns in food packaging, exquisite illustrations in cosmetics packaging, and product packaging require at least 1200dpi or higher.

considering equipment performance

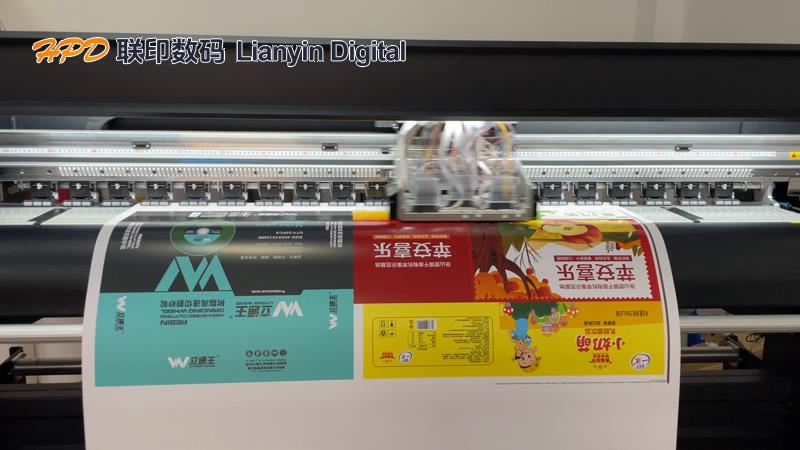

Printing resolution and speed are key performance factors. High resolution ensures clear image and text. In small batch packaging production, 600 × 600dpi is the basic threshold, and 1200dpi or above can present very high quality, which is sufficient to meet the needs of clients. Printing speed is measured by the number of pages or area per minute, and when choosing a digital printing device, a balance between speed and quality should also be considered. The nozzle technology affects the printing effect and cost. Piezoelectric nozzles have high precision and long lifespan but high price, while hot air bubble nozzles are the opposite. The number and arrangement of nozzles also affect printing efficiency and uniformity. The color management system ensures consistent colors for different batches of printing, and high-end devices support multi-color modes and ICC configuration files to accurately restore colors and enhance product competitiveness.

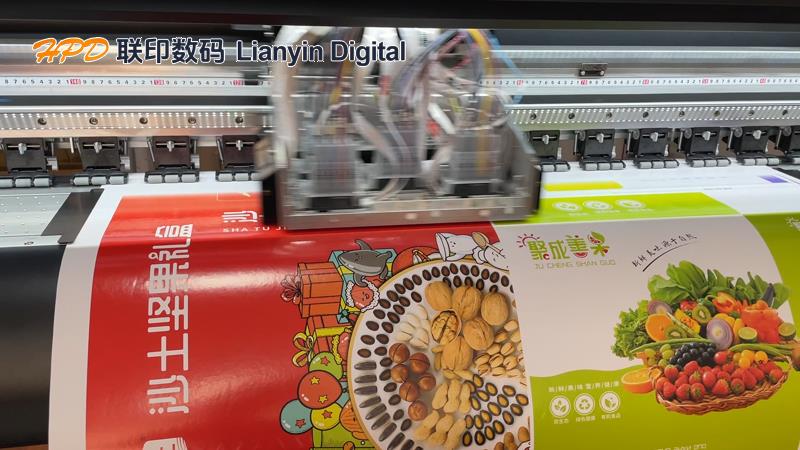

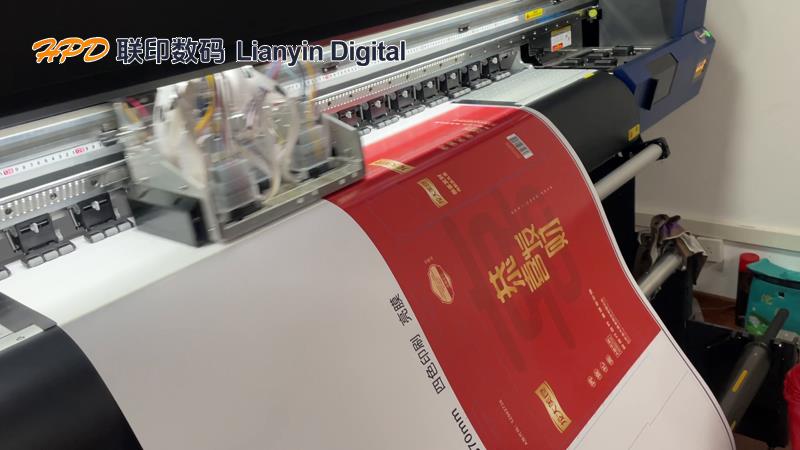

Packaging Box Digital Printing Machine

Integration of Solutions

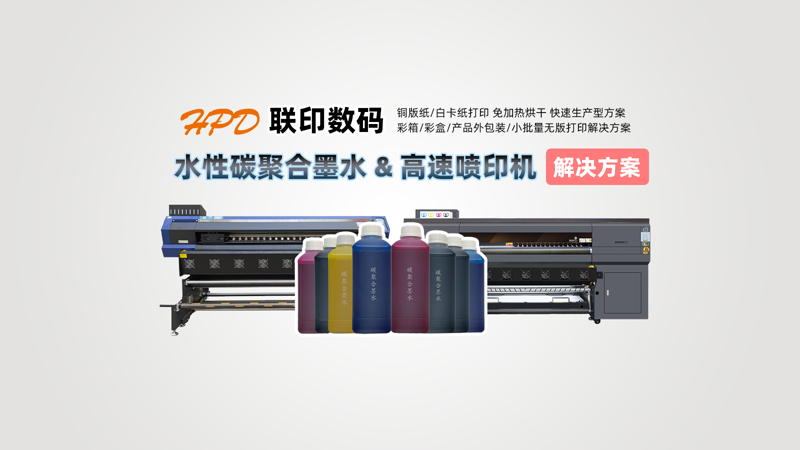

From the aspects of cost consumables, paper compatibility, and matching of packaging processes, suitable solutions need to be found for small batch packaging digital printing machines. The water based polymer carbon pigment ink of Lianyin Digital can achieve fast drying printing without drying and heating, significantly reducing production costs is a major highlight.

There are various packaging materials, and equipment selection needs to be widely compatible. From different types of paper such as corrugated paper, white cardboard, copperplate paper, to plastic film, label materials, metal foil, and even special media such as transparent film and adhesive stickers, the stronger the compatibility, the higher the flexibility of enterprise production, and the better it can meet the diverse customer needs.

4. Analyze cost factors Equipment procurement needs to match the budget.

Packaging digital printing machines are affordable and suitable for small businesses to produce in small batches. Although laser printing machines are expensive, they have high efficiency and are suitable for large-scale enterprises. In terms of consumable costs, inkjet digital printers should also pay attention to the average ink consumption cost and the stability of consumable supply. Maintenance costs are equally important. Equipment maintenance is simple, parts are easily accessible, and repair response is fast, which can reduce downtime losses and overall costs.

Fifth, brand and after-sales inspection

In addition to product stability and durability, a comprehensive service system is also a key factor in choosing suppliers. Including a wide coverage of after-sales outlets, a rapid response mechanism, a long warranty period, and professional training services, it can ensure the continuous and stable operation of equipment and provide support for enterprise production. In summary, choosing a digital printing small batch packaging printer requires a comprehensive consideration of printing needs, equipment performance, media compatibility, cost, brand after-sales, and other factors, combined with the actual situation of the enterprise, in order to select suitable equipment and seize market opportunities.