In the current trend of personalized consumption, the market demand for packaging and color box industry is showing a trend of small batch and diversification, and the traditional large-scale production mode is difficult to meet. Digital packaging printers, with their unique advantages, have become a key factor in activating the economic potential of small orders.

The Challenges and Opportunities of Small Order Economy in Packaging

Previously, the packaging industry focused on large-scale orders and pursued economies of scale.

. But as consumer demand becomes increasingly diverse, brand owners are launching more personalized products to attract the market, and packaging demand is also shifting towards small and multiple batches. The development of e-commerce has led to a surge in demand for personalized packaging among small and medium-sized businesses, with small order volumes; Rapid product updates and frequent changes in packaging design for brands have driven the growth of small order business. However, traditional printing and plate making have high costs, long production cycles, and poor flexibility, making it difficult to meet the demand for small orders. A set of printing plates costs thousands of yuan, and the cost allocation for small batch packaging orders is too high. Moreover, it takes several days or even weeks from plate making to printing, which cannot meet the requirements of fast delivery.

The three core advantages of digital printers

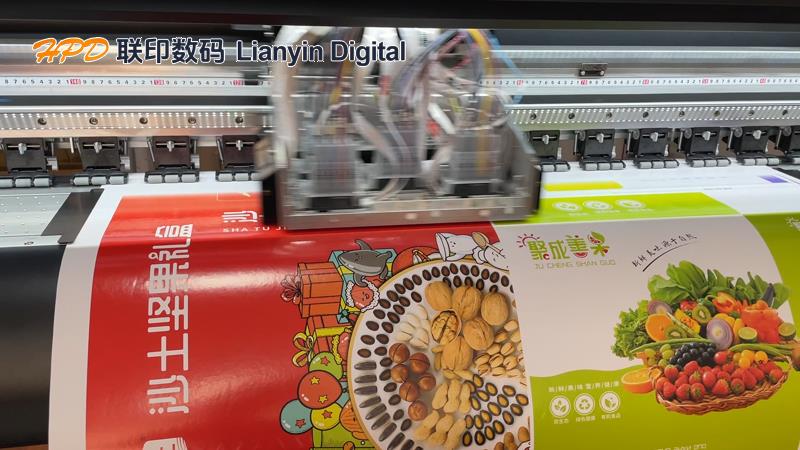

Digital printers bring a turning point to the economy of packaging small orders.

Firstly, there is no need for plate making, which significantly reduces costs. By using digital imaging technology, graphics and text can be directly printed onto packaging materials, saving the cost of plate making. Taking a small order of 100 color boxes as an example, the traditional offset printing plate making fee may be as high as thousands of yuan, while digital printing can be completely eliminated, resulting in a significant reduction in overall costs for small-scale production.

Secondly, one print to meet personalized needs. Whether it's unique patterns, text, or special sizes, they can be accurately presented. When beauty brands launch limited edition products, they use packaging box digital printers to customize color boxes with unique patterns to attract consumers and increase sales.

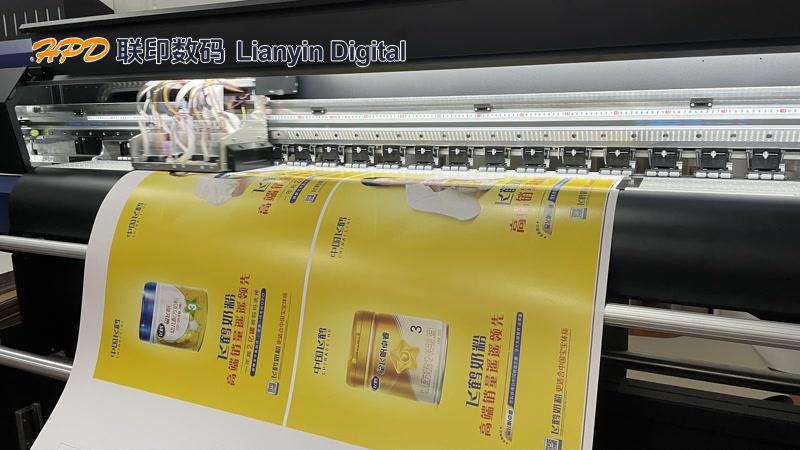

Thirdly, fast printing can shorten the delivery cycle. Digital printers have a short production cycle and can deliver products in just a few hours, while traditional printing processes take several days. Urgently replenish packaging color boxes before e-commerce promotions, and digital printers can quickly complete orders, helping products to be listed on time.

Packaging Box Digital Printer

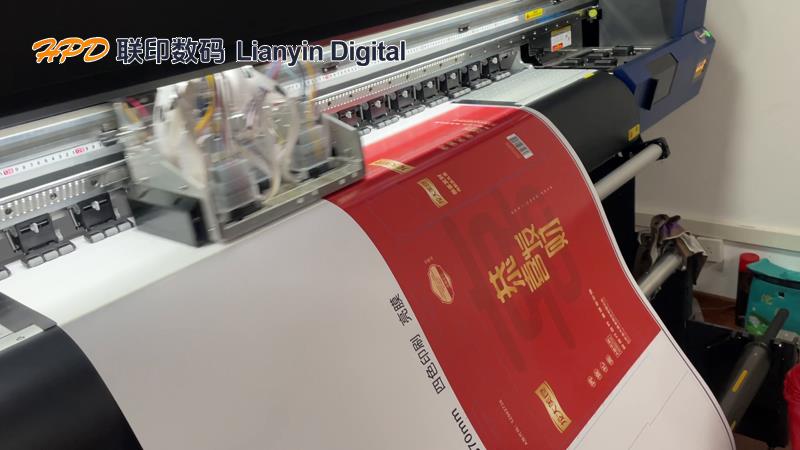

Accelerate the landing of creativity and industry innovation

In the traditional packaging design process, from the initial draft to the finished product, it requires multiple stages such as design, sampling, modification, plate making, and printing, which are time-consuming. The small batch digital printing machine simplifies the process, allowing designers to print directly after completing the design. If any problems are found and modified, they can be reprinted immediately, saving a lot of time and cost. This accelerates the implementation of corporate creativity and promotes innovative development. When food companies launch new flavor products, they use digital printers to make various packaging samples for testing, determine designs based on feedback, and produce in small batches, reducing the time from creativity to market by more than half.

Digital printers also bring many positive impacts. For small and medium-sized enterprises, their prices are low, operations are simple, and they can meet personalized production needs for small batches, helping them enter the packaging market and expand their business; It stimulates market innovation vitality, allowing enterprises to freely express their creativity, try new designs and materials; At the same time, on-demand printing avoids resource waste, optimizes resource allocation, and reduces enterprise operating costs.

In the current booming economy of packaging color boxes and small orders, digital printers are driving industry innovation with their advantages. Packaging companies should seize opportunities, embrace new technologies, and gain an advantage in market competition. Of course, the prerequisite is to find a suitable machine and a reliable digital printing machine manufacturer.

In the future, small batch digital printing machines will continue to innovate. The printing accuracy and quality will be further improved to meet the demands of the high-end market; The adaptability of materials will be expanded, allowing for high-quality printing on more materials such as plastic, metal, glass, etc; Combining IoT and big data technology to achieve intelligent production and management, remote monitoring, automatic maintenance, and optimized production and marketing.