In the printing industry, traditional printing technology has long dominated, but as market demand becomes increasingly diversified and personalized, its drawbacks are gradually becoming apparent. Especially with the surge in demand for small batch printing, plateless digital printing technology has become a new choice for many enterprises due to its unique advantages.

The solution of digital printing machines without printing plates is gradually demonstrating significant competitiveness in the field of small batch printing. Traditional printing faces many challenges in small-scale production. From the perspective of plate making, traditional printing requires a lot of time and cost to produce printing plates, and it is difficult to change the content after plate making, resulting in poor flexibility. In addition, small batch orders have meager profits, and the high fixed costs of traditional printing often make it difficult for enterprises to make profits when undertaking such orders.

The plateless digital printing technology perfectly avoids these problems. Its biggest feature is the absence of plate making, which directly transmits graphic and textual information to the printer through the computer, omitting the plate making process and greatly shortening the production cycle. After receiving small batch printing orders, enterprises can start production immediately without waiting for plate making, greatly reducing the time from receiving orders to delivery and greatly improving response efficiency.

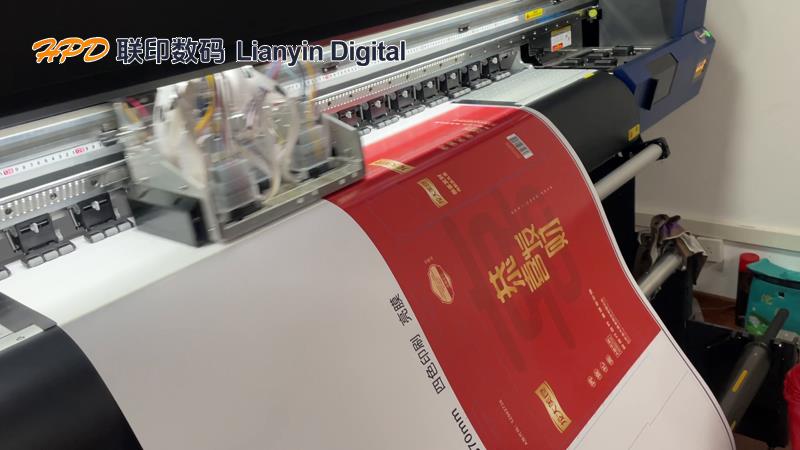

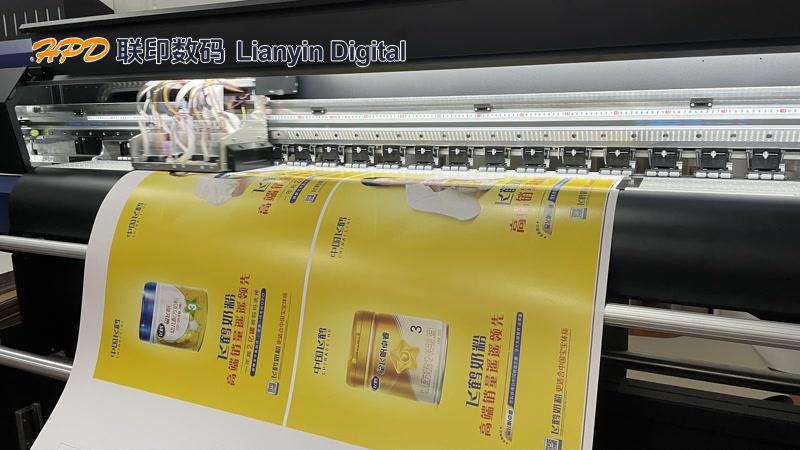

In terms of producing scattered orders, digital printing machines and equipment also demonstrate a high degree of flexibility. It can achieve fast switching between different orders, and each file can be independently designed without the need to readjust equipment. Whether it's posters, business cards, or personalized packaging, it can easily handle them. Moreover, digital printing supports variable data printing, allowing for personalized customization of content and patterns for the same batch of printed materials, meeting diverse customer needs that traditional printing cannot match.

From a cost perspective, the advantages of the non plate digital printing machine solution are significant. Due to the absence of plate making, the cost of plate making materials, labor, and equipment loss is saved, effectively controlling the cost of small batch printing. At the same time, the on-demand printing mode avoids inventory backlog, reduces warehousing costs, and makes enterprise capital turnover more flexible.

In terms of environmental protection, plateless digital printing machine also has more advantages. Traditional printing and plate making processes generate wastewater, exhaust gas, and solid waste, causing environmental pollution; Digital printing does not involve plate making and has a high ink utilization rate. In small batch color box packaging, environmentally friendly water-based ink is often used, such as the environmentally friendly carbon polymer pigment ink of Lianyin Digital, a high-speed printing production ink with environmental testing certification, which is in line with the current trend of green printing development.

Driven by the digital wave, the demand for small batch and personalized printing will continue to grow. The digital printing machine solution has opened up a new track for printing enterprises with its advantages of no plate making, high efficiency and flexibility, controllable cost, and green environmental protection. Whether it is advertising companies, cultural and creative enterprises, or e-commerce merchants, choosing plateless digital printing technology can seize the opportunity in the small batch printing market and achieve efficient and accurate production goals.