In the current booming commodity economy, packaging is not only the protective shell of products, but also an important carrier of brand image. Large size color box packaging plays a crucial role in logistics transportation, product display, and other scenarios due to its eye-catching and intuitive visual effects. However, traditional printing methods face many challenges in the production of large-sized color box packaging, while the emergence of digital printing technology is like a dawn, bringing new solutions and development opportunities to this field.

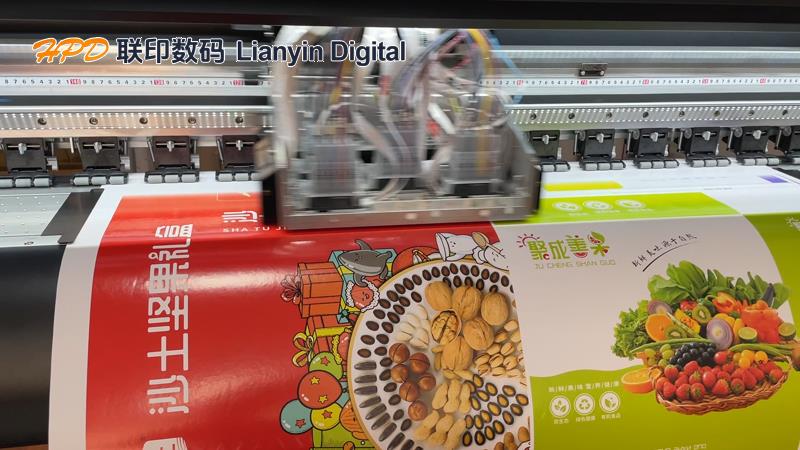

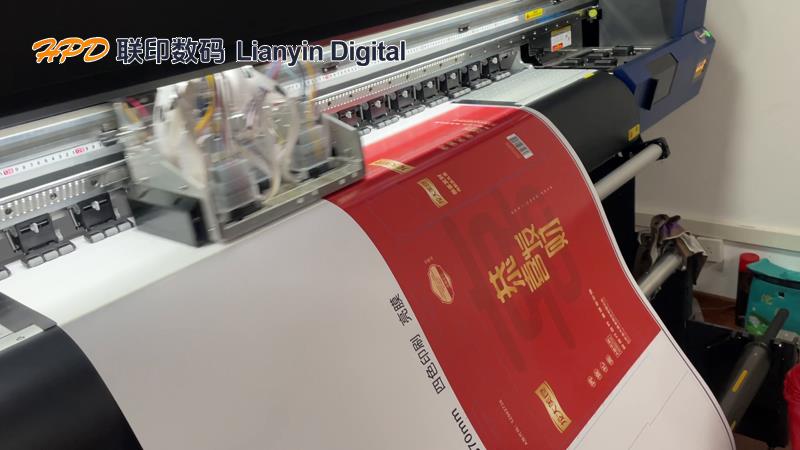

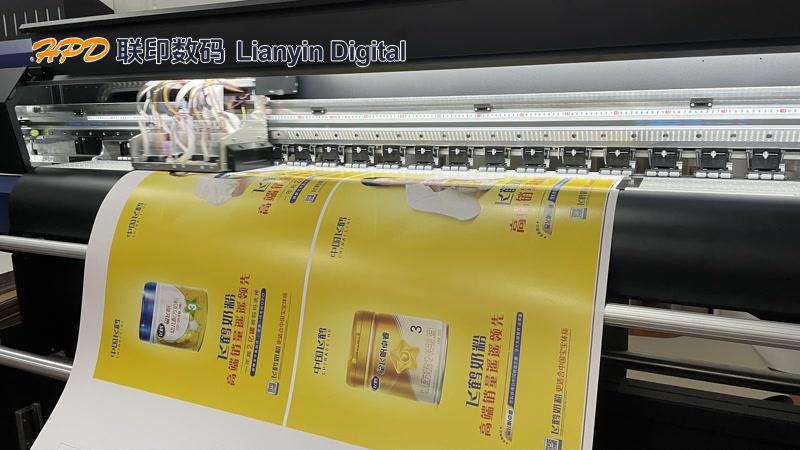

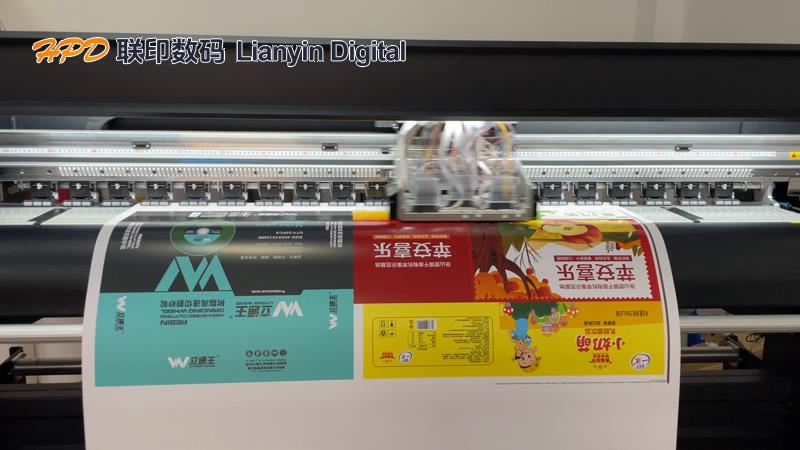

Traditional printing has obvious shortcomings in the production of large-sized color boxes. In addition to the time-consuming and costly production of printing plates, traditional printing machines find it difficult to achieve such large widths of 1.6 meters, 1.8 meters, or even larger. The larger the width, the more expensive the plate making fee will be. Traditional printing equipment has high requirements for the site and environment. The printing, drying, cutting and other processes of large-sized color boxes require a large amount of space, which increases the operating costs of enterprises. Moreover, the production cycle is long, making it difficult to meet the rapidly changing needs of the market. Digital printing technology effectively overcomes the aforementioned challenges and demonstrates powerful advantages. For example, the four head digital printing machine of Lianyin Digital can print a width of 1.8 meters and an infinite length.

In addition, in terms of production flexibility, digital printing does not require plate making and directly transfers design patterns to printing equipment through computers. The process from design finalization to finished product output is greatly simplified and can quickly respond to customer needs. Whether it is small batch customization or large-scale production, it can be easily handled. For enterprises, this means they can undertake more diverse orders, expand their business scope, and enhance their market competitiveness.

Digital printing also performs well in terms of production efficiency and cost control. It has a high degree of automation, and the equipment can operate continuously, greatly shortening the production cycle. Compared to traditional printing machines that cost hundreds of thousands or even millions, the price of digital printing machines without printing plates is also affordable, with a machine suitable for small batch production at a price of less than 100000 yuan. Meanwhile, as there is no need for plate making, the material, labor, and time costs in the plate making process are reduced; The on-demand inkjet printing method also avoids ink waste and further reduces production costs.

In addition, digital printing can also achieve variable data printing, which means that in the same printing process, the pattern and text of each color box can be different. This feature is very attractive for enterprises that need to label different product information and promotional information on the packaging.

In terms of environmental protection, digital printing also demonstrates significant advantages. The ink used in traditional printing processes contains many volatile organic compounds (VOCs), which are emitted into the atmosphere during printing and drying, causing environmental pollution; The water-based ink or UV ink used in digital printing has better environmental performance and almost no harmful gas emissions during the production process, which is in line with the current trend of green environmental protection and also meets consumers' demand for environmentally friendly packaging. From a long-term development perspective, digital printing technology still has strong scalability and upgrade potential. With the continuous advancement of technology, the accuracy, speed, and stability of digital printing equipment will continue to improve, which can meet the production needs of large-sized color box packaging with higher standards.

At the same time, the integration with technologies such as the Internet of Things and big data will enable intelligent management of digital printing production, further optimize production processes, and improve production efficiency and product quality. Digital printing technology, with its significant advantages in flexibility, color expression, production efficiency, cost control, environmental protection, etc., has become an ideal choice for the production of large-sized color box packaging.

In the context of increasingly fierce market competition and constantly upgrading consumer demand, packaging companies should actively embrace digital printing technology, grasp industry development trends, achieve their own transformation and upgrading and sustainable development, and inject new vitality and creativity into the product packaging field.