In the packaging printing industry, although traditional offset printing methods perform well in large-scale production, they are inadequate when facing small batch and multi variety orders. This is because offset printing requires the production of printing plates, which not only have long production cycles and high costs, but also have requirements for printing volume, start-up costs, etc., making the cost of small-scale production too high. The printless printing technology of digital packaging color printing machines has achieved an integrated process from design to printing. It does not require the production of printing plates, breaking the traditional reliance on printing plates and greatly simplifying the printing process. In small-scale and individual production, digital packaging printing machines have demonstrated many significant advantages in printless printing.

1、 Cost advantage

Whether it is relief, intaglio or flexographic printing, traditional printing plate making is an essential step. For medium and high-speed machines, the cost of plate making is particularly high, and in the comprehensive cost of some small batch orders, plate making even accounts for a large part. The non plate printing technology of digital packaging color printing machines completely saves the cost of plate making.

Under traditional printing methods, companies need to keep printed copies for customers, even if they may only use them once every few years. This leads to the need for specialized warehouses to store a large number of printing plates, which not only increases the cost of storage space, but also significantly increases the difficulty and cost of enterprise management. Digital plateless printing does not require the retention of printing plates, and companies do not need to worry about this, effectively reducing inventory costs.

2、 Flexibility advantage

1. Flexibly adjust printing content

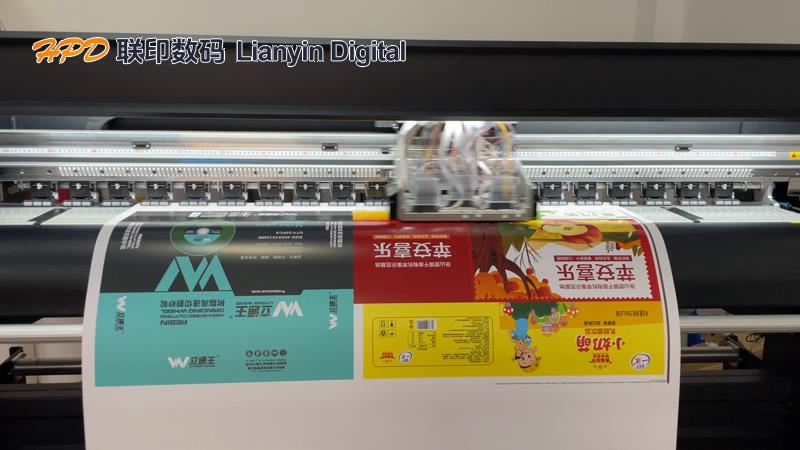

The plateless printing technology of inkjet digital box printer makes the adjustment of printing content extremely simple. During the printing process, real-time changes to the printed content can be achieved by modifying electronic files on the computer. This feature is particularly important for companies that need to frequently adjust packaging information. Enterprises can easily implement these changes without the need to remake the plate like traditional printing, greatly improving production flexibility.

2. Advantages of urgent and supplementary orders

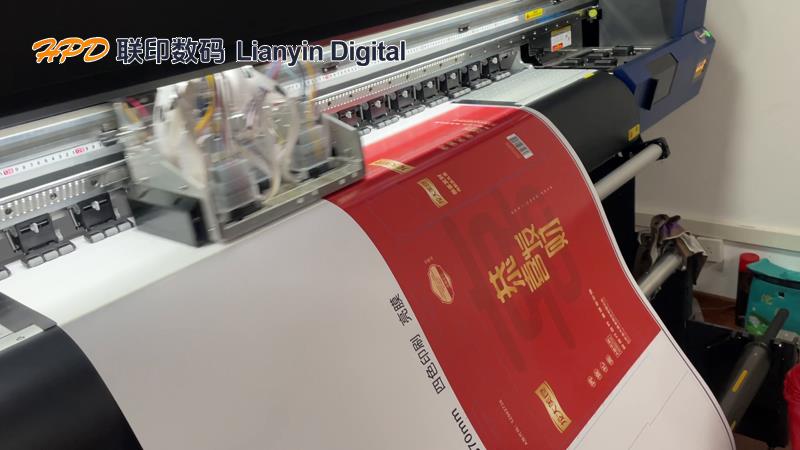

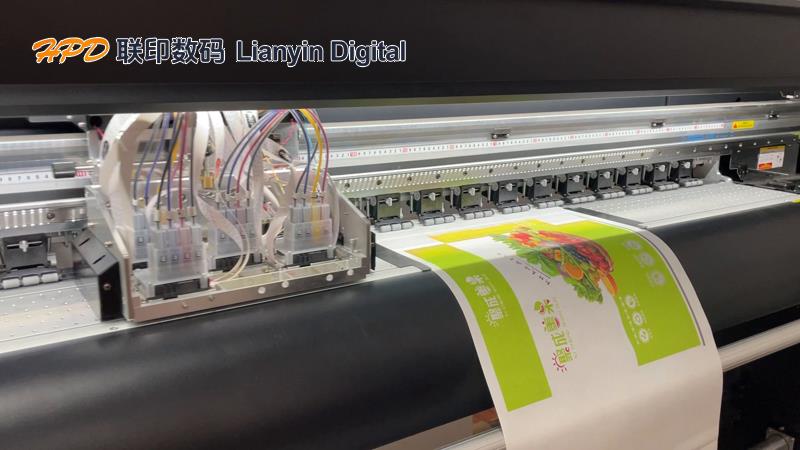

In today's fiercely competitive market, enterprises often face urgent orders from customers or require urgent restocking due to market sales exceeding expectations. Traditional printing methods often struggle to meet customers' urgent needs due to long plate making time and cumbersome startup preparation when faced with these situations. Digital packaging color printing machines are different. They can be turned on for printing at any time, without the need for long preparation work, and can quickly respond to urgent and supplementary orders.

3. Adapt to multiple materials and specifications

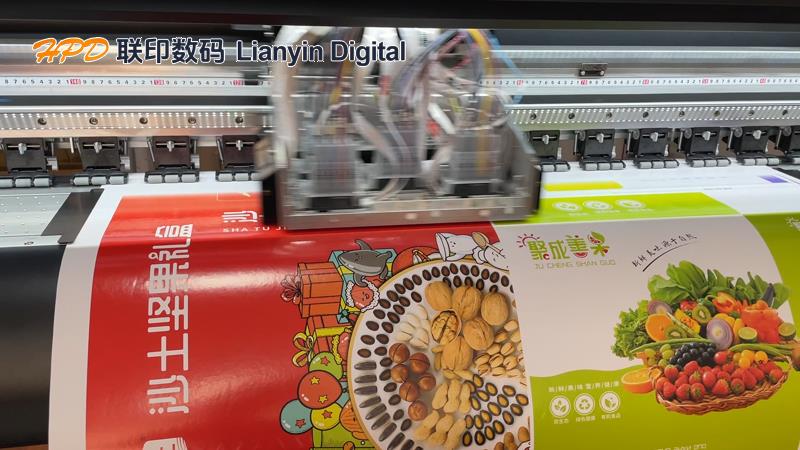

Digital packaging color box printing machines can adapt to a variety of printing media with different materials and specifications. Whether it is common corrugated board, cardboard, or some special materials, such as foam board, composite materials, it can achieve high-quality printing. Moreover, digital printing machine can easily handle products of different specifications, such as cardboard boxes of varying sizes, without the need for complex equipment adjustments. This enables enterprises to more flexibly meet the diverse needs of customers and expand their business scope when accepting orders.

4. Personalized customization

With the increasing demand for personalized products from consumers, personalized packaging customization has become a new trend in the market. The flat printing technology of small batch digital printing machines provides strong support for personalized customization. It can achieve "one printing, different pieces", and enterprises can create unique packaging for each product according to customers' specific requirements.

3、 Environmental advantages

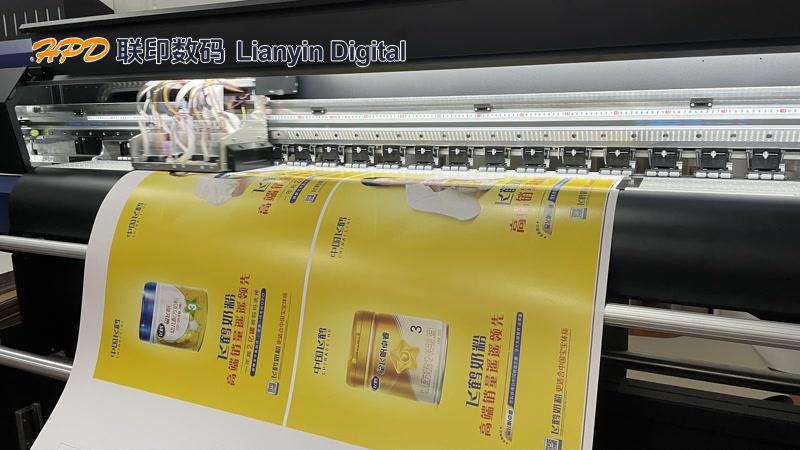

In the traditional printing process, the plate making process generates a large amount of wastewater, exhaust gas, and waste residue, causing serious pollution to the environment. In addition, the ink diluents used in traditional printing are mostly organic solvents, which are substances subject to strict policy control. The ink used in digital packaging color printing machines is usually water-based ink, which is more environmentally friendly. For example, the ink used in cardboard digital printing machines meets the non-contact food grade requirements, complies with the requirements of the European Union, the United States, and China for food packaging, and achieves zero emissions during the production process. This not only conforms to the social responsibility of enterprises, but also helps them comply with the requirements of environmental policies and enhance their corporate image.

The plateless printing technology of packaging digital printer in small batch production is gradually changing the pattern of the packaging printing industry with its many advantages such as low cost, short time, high flexibility, and environmental protection. With the continuous advancement of technology and further promotion of market demand, digital printing technology will be widely applied in more fields, bringing more opportunities and development space to enterprises, and helping them stand out in the fierce market competition.