In today's consumer market, the trend of personalization and customization is becoming increasingly prominent. As the "facade" of a product, the precision of the design and production of high-end packaging gift boxes directly affects the attractiveness and brand image of the product. In the past, traditional printing often encountered difficulties when facing small batch customized orders due to high plate making costs and long cycles. Digital printing machines can quickly provide customers with customized gift box solutions. The rise of demand for small batch customization: Consumers' pursuit of personalized products is constantly increasing.

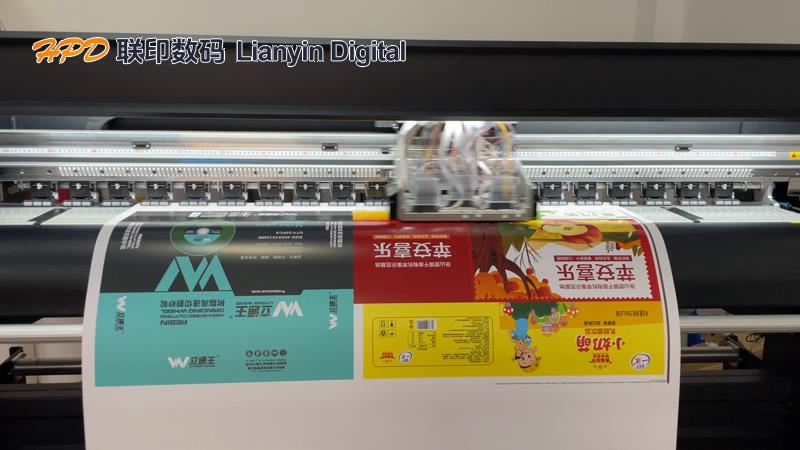

From high-end gifts and jewelry to specialty foods, high-end cosmetics and other industries, they all hope to showcase the uniqueness and brand value of products through unique packaging gift boxes. Small batch customization can not only meet the personalized service needs of different customers for enterprises, but also reduce inventory costs and flexibly respond to market changes. For example, some high-end jewelry brands will customize exclusive gift boxes for limited edition jewelry to highlight its unique quality; Specialty food companies will launch customized small batch gift boxes based on different holidays or customer needs to enhance the attractiveness and market competitiveness of their products.

Advantages of Scanning Digital Printers

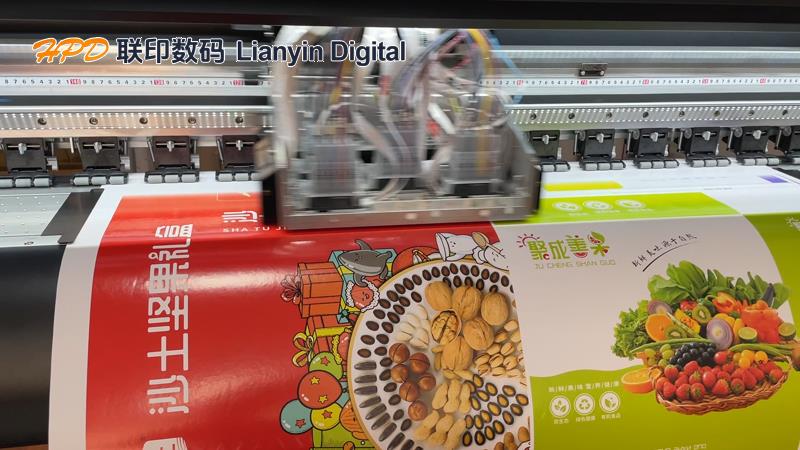

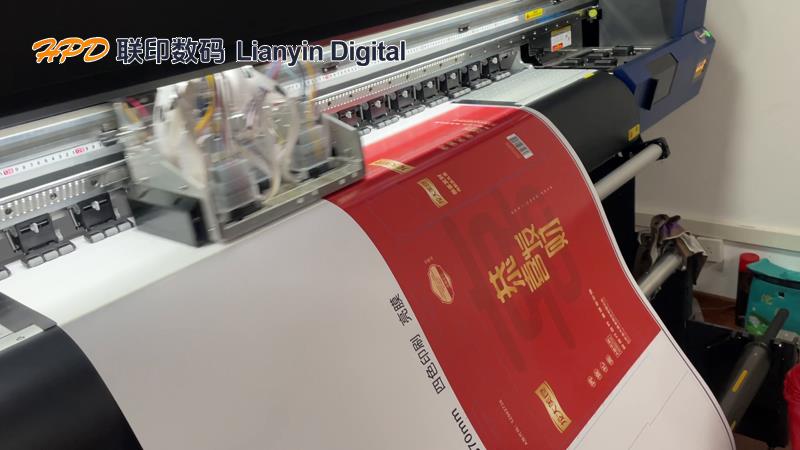

Fast Delivery: Plateless printing machine, can directly print design files on packaging gift boxes. The entire process from finalizing the design to outputting the finished product can be completed in a short amount of time. Compared to traditional printing, which requires multiple complex processes such as typesetting, plate making, and printing, it greatly shortens the production cycle. When facing urgent orders or customized needs for small or multiple batches, scanning digital printers can respond quickly, ensuring timely delivery of products and meeting customers' strict requirements for time.

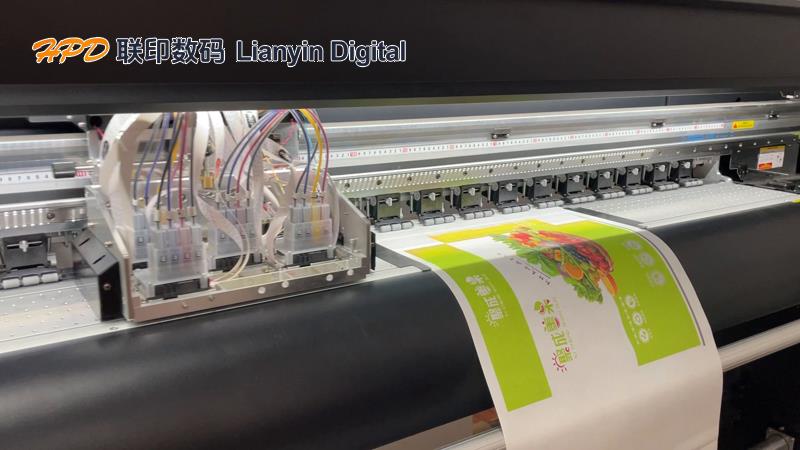

Excellent quality: This type of printer has high-precision printing technology, which can clearly present delicate patterns, tiny text, and rich color layers. High printing resolution and excellent color reproduction, whether it is exquisite and complex patterns or gradient color effects, can be accurately output. For example, when printing high-end cosmetics gift boxes, it is possible to perfectly present the product's brand logo, delicate product images, and exquisite decorative patterns, enhancing the overall quality and visual impact of the gift box.

Highly flexible: It can be printed on packaging gift boxes of different materials and shapes, such as paper, wood, plastic, metal, as well as gift boxes of various shapes such as square, circular, and irregular.

Enterprises can freely choose suitable gift box materials and shapes based on product characteristics and design requirements, and printers can easily handle them, achieving diversified customized effects.

Cost effectiveness: For small-scale production, packaging gift box printers avoids the high costs of traditional plate making. Each printing only requires the consumption of consumables such as ink and paper, effectively reducing production costs. At the same time, it reduces the cost of duplicate plate making and inventory backlog caused by plate making errors, and improves the economic efficiency of the enterprise.

Types and selection points of gift box printers

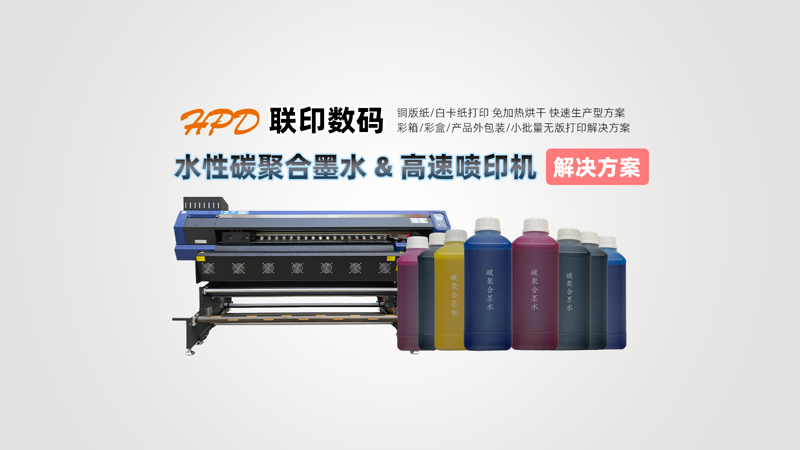

Digital inkjet printers: Rich in color expression, capable of printing gradient colors and high saturation images. When choosing, pay attention to the number and type of nozzles. Multiple nozzles can improve printing speed, and different types of nozzles have differences in accuracy and ink compatibility; The environmental friendliness of ink cannot be ignored, especially for gift box printing in fields such as food and cosmetics. It is necessary to ensure that the ink meets relevant safety standards. For example, the carbon polymer pigment ink of Lianyin Digital has four major testing certifications, which can be safely applied in food and medical fields.

UV flatbed printer: It can print on various flat materials, and through UV curing ink, the printed patterns have good adhesion and wear resistance. When choosing, attention should be paid to the accuracy and stability of the nozzle. High precision nozzles can achieve finer printing effects; The printing speed of the machine is also important and can affect production efficiency; In addition, the quality and color gamut range of ink determine the richness and vividness of printed colors.

Laser printer: Fast printing speed, high clarity of text and lines, suitable for printing gift boxes with a lot of text information. When selecting, consider the resolution of the printer, as high resolution can make the text edges sharper; The capacity of the paper box affects the continuous printing ability.

For enterprises with high demand for batch printing, a larger paper box capacity is more suitable; Meanwhile, pay attention to the maintenance costs and consumables prices of the printer. In the high-end packaging gift box market dominated by small batch customization needs, scanning digital printers have become a powerful tool for enterprises to enhance competitiveness due to their advantages of fast delivery, high-quality output, high flexibility, and cost-effectiveness. When choosing gift box printers, enterprises need to comprehensively consider the characteristics of different types of printers based on their own business needs, budget, and requirements for product quality.