As a visual display of brand image and an important carrier of product protection, the design and production of product packaging boxes have become increasingly important. At the same time, market demand tends to favor small batch personalized customization, with scattered orders occupying a large share. Traditional printing methods often expose many limitations when facing diverse demands, while the rise of digital printing technology has injected a strong innovative vitality into individual printing, leading the industry towards a new stage of development.

Packaging box digital printer opens up small batch efficient production mode

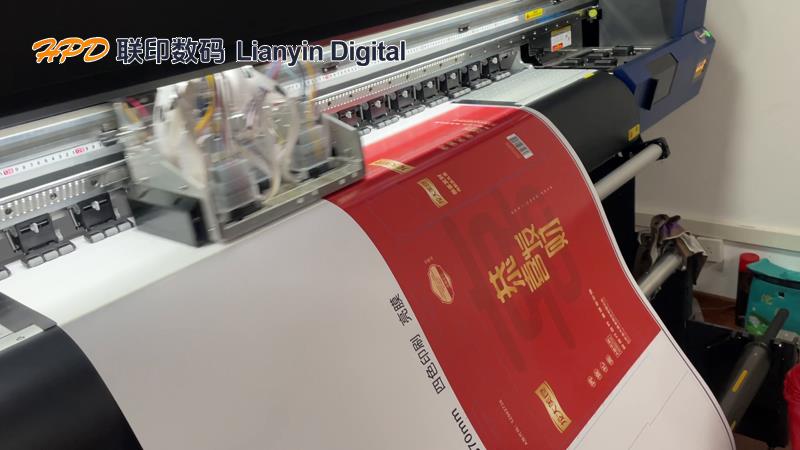

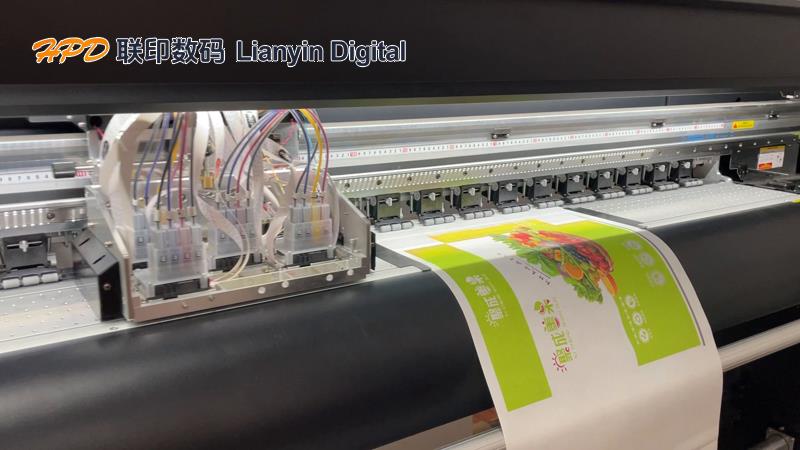

Digital printing technology abandons the time-consuming and laborious process of plate making in traditional printing. It directly transfers the designed electronic files to a digital printer through a computer, accurately inkjet prints them onto the surface of the packaging box, and quickly presents exquisite patterns and text. This direct imaging method greatly simplifies the production process, significantly reducing the time from design finalization to finished product output, providing strong support for enterprises to quickly respond to market demand.

The excellent choice for small-scale production significantly improves cost-effectiveness

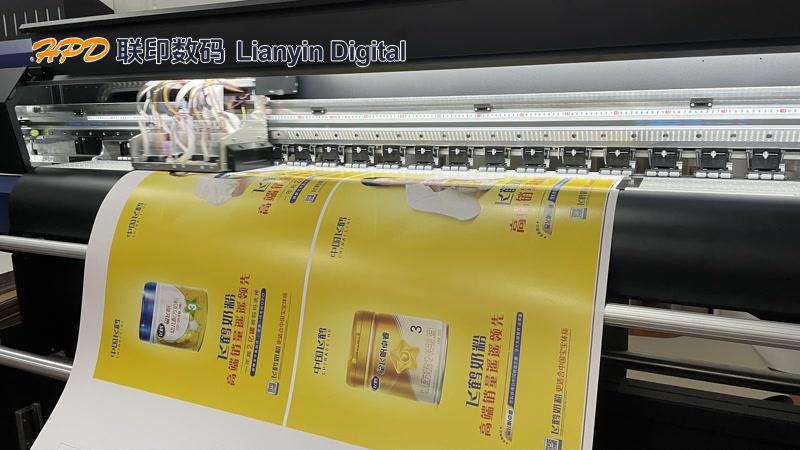

In traditional printing, the cost of plate making accounts for a large proportion of the total cost, and the plate making process requires a lot of time and materials. For small-scale packaging box production, the high plate making cost is spread over a limited number of products, resulting in high unit costs. Digital printing eliminates the need for plate making, completely eliminating this cost item and optimizing the cost structure of small-scale production. At the same time, the on-demand printing feature of digital printing avoids inventory backlog caused by overproduction, further reducing the operating costs of enterprises.

Highly flexible customized services

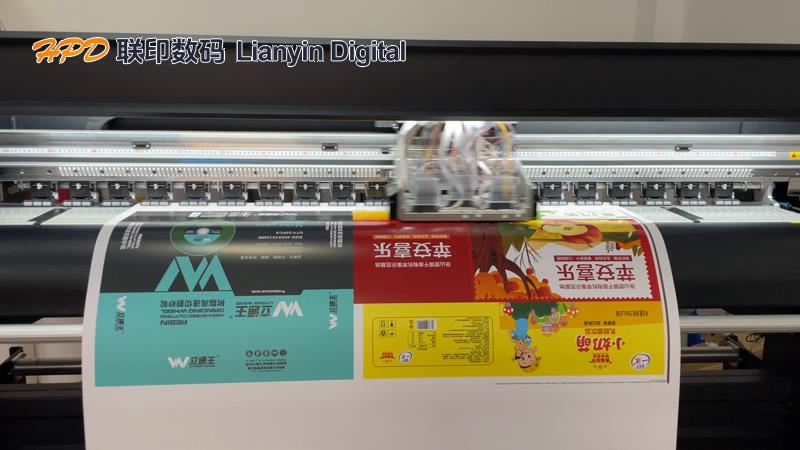

The increasing diversity of consumer demands has prompted companies to seek differentiation and personalization in product packaging. With the advantage of digital printing, packaging digital printers can easily achieve customized production of packaging boxes. Whether it's unique brand logos, personalized patterns for different customers, or information changes based on product batches and promotional activities, digital printing can respond quickly. Enterprises can print multiple different designs on the same batch of packaging boxes to meet the needs of market segmentation.

Fast delivery, seize market opportunities

In a fast-paced business environment, the speed of product launch directly affects a company's market performance.

Packaging Box Digital Printer

Digital printing technology has greatly shortened the production cycle of packaging boxes. Traditional printing, from plate making, proofreading to batch printing, may take several days or even weeks for the entire process, while digital printing can complete printing in a short period of time after receiving design files, achieving same day or next day delivery. This has unparalleled advantages for packaging needs of new product launches, urgent orders, or seasonal products. Enterprises can push products to the market faster and seize fleeting market opportunities.

Challenges and coping strategies faced

Printing speed and production capacity bottleneck

Compared to traditional large-scale printing equipment, the printing speed and production capacity of digital printers are limited to a certain extent, especially when facing large-scale orders, it may be difficult to meet the requirements of fast shipping.

Color Management and Printing Quality Stability

There are differences in color reproduction and color gamut range among digital printers of different brands and models, and quality issues such as color deviation and uneven ink dots may occur during long-term continuous printing, affecting the printing quality of packaging boxes. To solve the problem of color management, the industry has introduced professional color management software, which ensures color consistency and accuracy by accurately calibrating printers, ink, paper, etc. When choosing a digital printing service provider, enterprises should prioritize suppliers with a comprehensive color management system and quality inspection process.

With the continuous advancement of technology and the evolving market demand, digital printing technology for packaging boxes will show broader development prospects. In terms of technological innovation, digital printing devices with higher resolution, faster printing speed, and wider color gamut will continue to emerge, further improving printing quality and efficiency.

At the market application level, digital printing will be popularized in more industry sectors, especially in the packaging needs of niche brands, creative products, and short-term marketing activities, playing a leading role. The packaging box digital printer has injected new vitality into the industry and will continue to lead innovative changes in the packaging production field.