In the continuous development of the printing industry, cost control has always been a core issue of concern for enterprises. Digital printing machines are now widely used in various industries for printing production, and are not a new thing anymore. Compared with traditional printing machines, both have their own advantages in reducing costs. Analyzing their respective advantages and disadvantages can help printing companies choose equipment reasonably and make good production plans.

1、 Plate making cost

Traditional printing machines must go through the plate making process before printing, which involves multiple cost expenditures such as purchasing plate making equipment, purchasing plate materials, and hiring professional plate making personnel. The cost of a regular PS plate may range from tens to hundreds of yuan, and if complex patterns or fine printing requirements are encountered, the plate making cost will increase significantly. And once the printed content is modified, it needs to be remade, resulting in a secondary waste of costs. In addition, the maintenance and updating of plate making equipment also require continuous investment of funds.

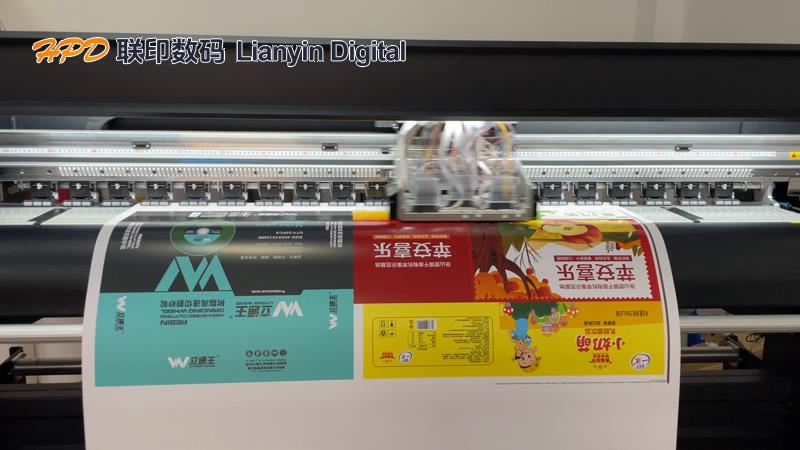

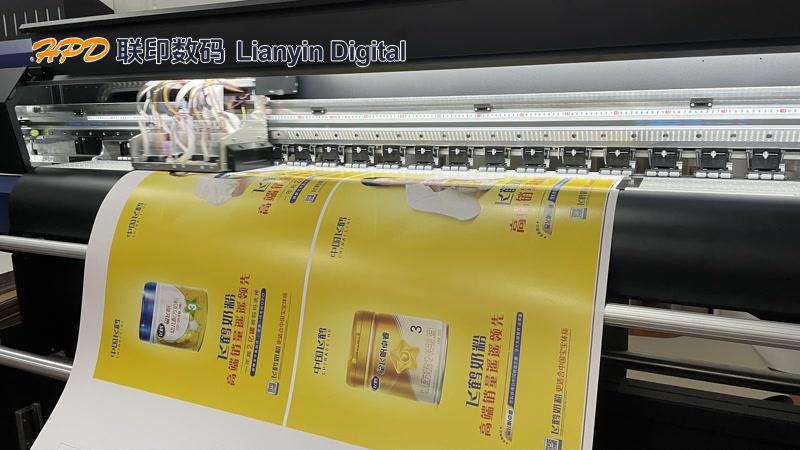

Digital printing machines completely eliminate the plate making process and directly convert digital files into printed products. This not only avoids various costs during the plate making process, but also saves the time cost required for plate making. For some temporary and short cycle printing tasks, the advantage of digital printing without plate making can quickly respond to demand, reduce potential losses caused by waiting time, and greatly reduce overall costs.

2、 The relationship between printing quantity and cost

Traditional printing machines have significant economies of scale. In large-scale printing, fixed costs (such as plate making, equipment depreciation, etc.) can be allocated to more printed materials, and the unit printing cost will significantly decrease with the increase of printing quantity. For example, when printing tens of thousands of color boxes, the unit cost of traditional printing may be much lower than that of digital printing. However, when the printing quantity is small, the allocation of fixed costs is insufficient, and the unit cost will increase significantly. Therefore, traditional printing is not suitable for small batch, personalized printing business.

The cost structure of digital printing machines is more suitable for small-scale printing. It has no minimum printing quantity limit, and whether printing one or multiple copies, the cost change is relatively small, so there will be no situation where the cost is abnormally high due to a small quantity. For businesses that require frequent replacement of printed content and personalized customization, such as customized business cards and small batch personalized brochures, digital printing can meet the needs at a lower cost. But as the number of prints increases, the disadvantages of digital printing in terms of ink, paper, and other consumables costs will gradually become apparent. When a certain printing volume is reached, its unit cost will be higher than traditional printing.

3、 Consumables cost

Traditional printing machines are difficult to achieve precise control over ink usage, especially when printing large areas of color blocks or complex patterns, which can lead to excessive use of ink and result in ink waste. Meanwhile, traditional printing has strict requirements for paper specifications, making it difficult to flexibly utilize irregular paper such as scraps, resulting in relatively low paper utilization rates.

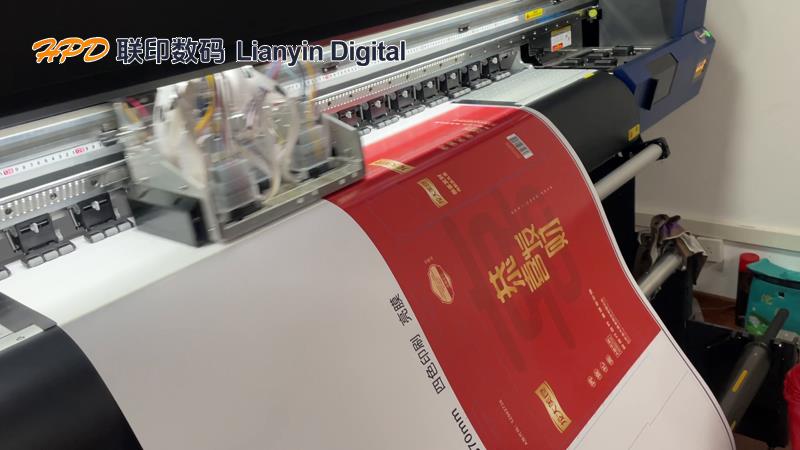

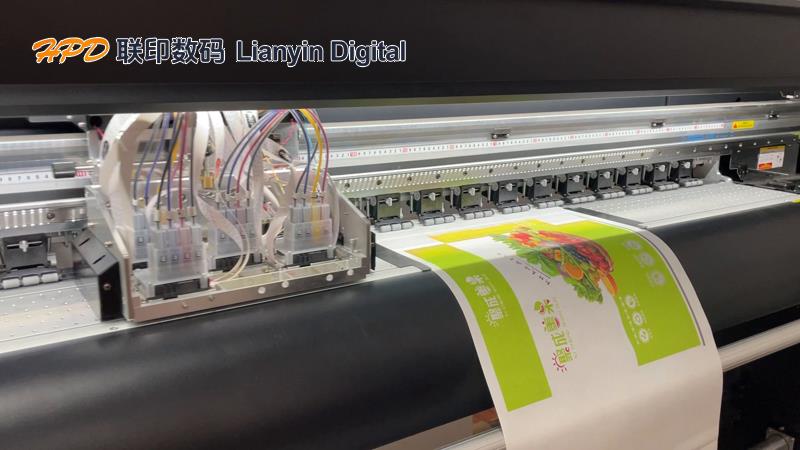

Digital printing machines adopt advanced nozzle technology and ink droplet control technology, which can accurately allocate ink usage according to printing content, greatly reducing ink waste. Moreover, digital printing has stronger adaptability to paper, allowing for flexible adjustment of printing layout according to actual needs, making full use of irregular paper, improving paper utilization, and reducing consumable costs. However, the procurement cost of ink and special paper consumables used in digital printing may sometimes be higher than that of ordinary consumables used in traditional printing.

4、 Human and equipment maintenance costs

The operation process of traditional printing machines is complex, requiring professional operators to perform plate making, printing equipment debugging, color management, and other tasks, resulting in high labor costs. Moreover, traditional printing equipment has complex structures and numerous components, making daily maintenance and repair difficult and costly, requiring regular equipment maintenance and component replacement.

The automation level of digital printing machines is relatively high, and the operation is relatively simple. Personnel who have received basic training can operate them, reducing the demand for professional operators and thus reducing labor costs. Its equipment structure is relatively simple, and the maintenance difficulty and cost are also relatively low. However, the key components such as the nozzle of digital printing machines are relatively precise and have certain maintenance limitations. Because once a malfunction occurs, the repair cost is high, and the maintenance of some high-end digital printing equipment relies on professional technical personnel from the manufacturer.

Both digital printing machines and traditional printing machines have their own advantages, disadvantages, and applicable scenarios in reducing costs. Traditional printing is suitable for large-scale and standardized printing tasks, reducing costs through economies of scale; Digital printing has cost advantages in small batch, personalized printing, and quick response to demand. Printing enterprises should comprehensively consider factors such as their own business type, order size, and cost budget, and choose printing equipment reasonably to achieve effective cost control and maximize economic benefits.