In the packaging printing industry, traditional offset printing has long dominated, especially suitable for large-scale printing. However, when faced with small batch packaging printing orders, the traditional printing mode exposes many drawbacks. The plate making and opening process is not only expensive, but also time-consuming, which is undoubtedly a huge obstacle for enterprises that pursue efficiency and cost control. In this context, printless digital printing technology has emerged, and packaging box printing machine have brought a new solution to the small batch printing market.

Significant cost advantage

The feature of digital printing machines that do not require plate making has fundamentally reduced the cost of plate making. For small batch orders, this advantage is particularly prominent. Traditional printing and plate making can cost thousands of yuan, while digital printing completely eliminates this expense. In addition, digital printing for on-demand production reduces the risk of inventory backlog, avoids waste caused by overproduction, and further lowers overall costs. According to statistics, using digital printing technology can reduce the cost of small batch printing by 30% to 50%.

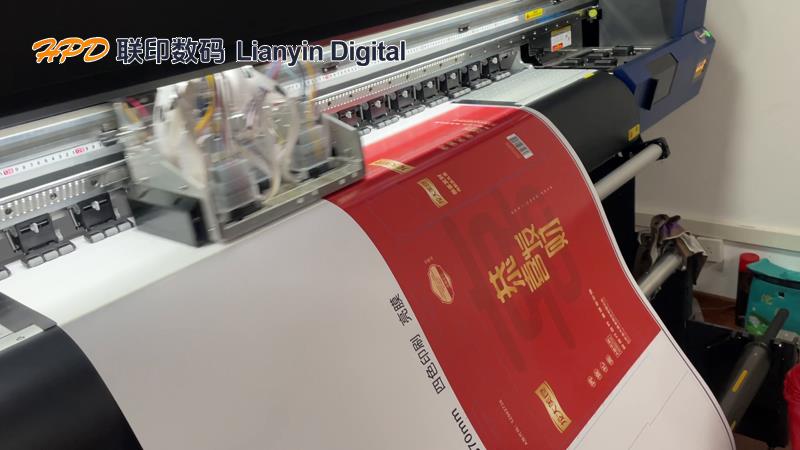

Convenient and efficient operation

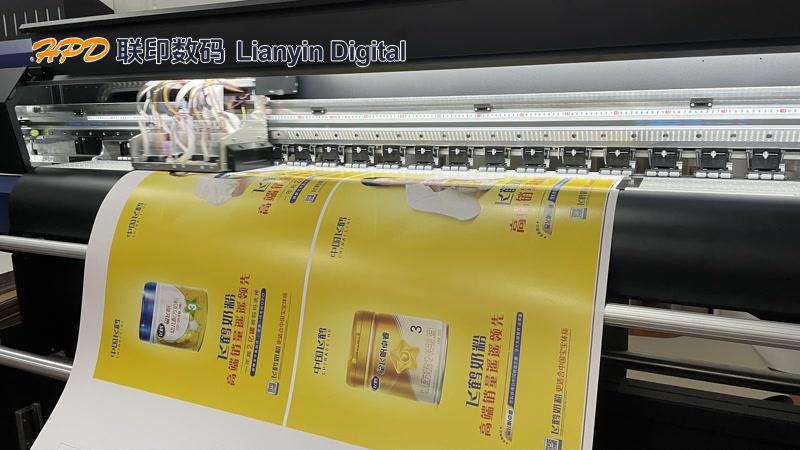

The digital printing operation is extremely simple, and the staff only need to transfer the design file to the digital printing machine through the computer to start the printing process. Compared to the complex plate making and proofreading process of traditional printing, digital printing greatly shortens the preparation time. Even beginners with no printing experience can proficiently operate digital printing machines after simple training, which enables companies to quickly respond to market demand and improve service efficiency.

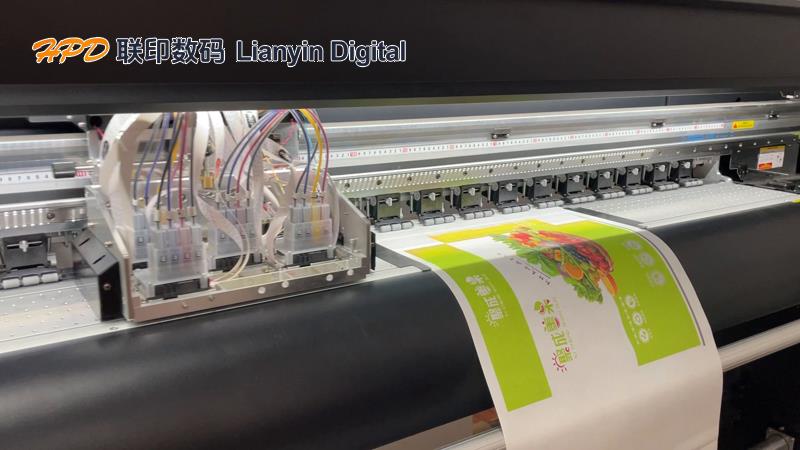

Simplified production process

The traditional printing production process is lengthy, involving multiple stages such as design, plate making, printing, die-cutting, etc. Each stage needs to be strictly controlled, otherwise quality problems are prone to occur. Digital printing greatly simplifies the production process, directly from digital files to finished product output, reducing human intervention in intermediate links, lowering the probability of errors, and also speeding up overall production speed. Small batch printing orders that originally took several days to complete can now be delivered in just a few hours through digital printing.

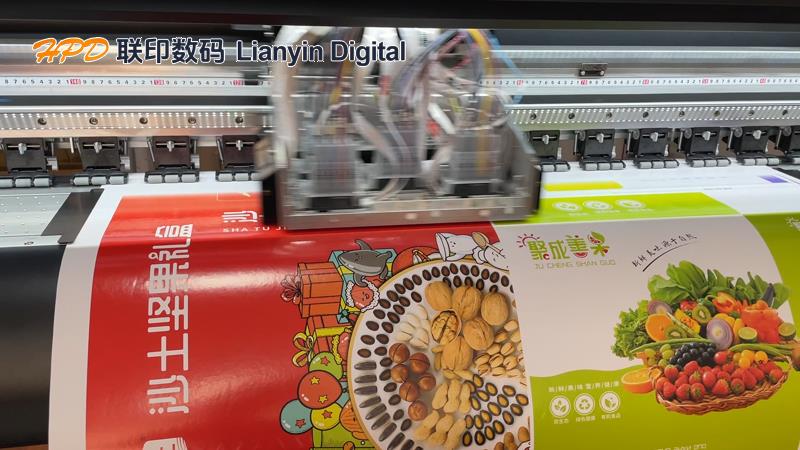

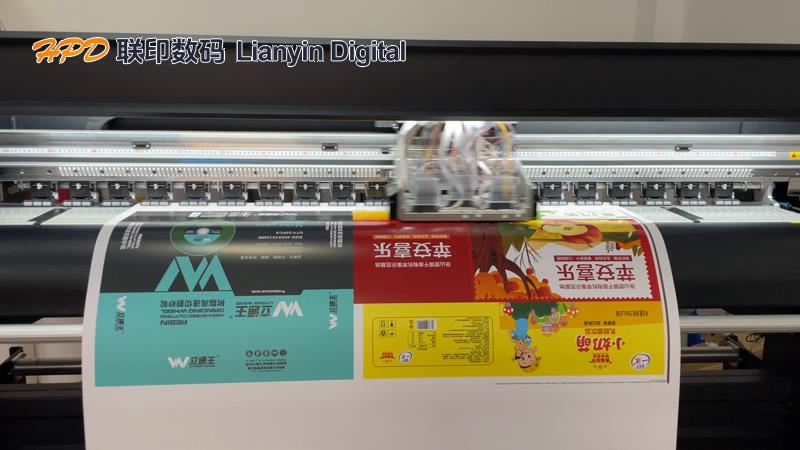

Widely applicable scenarios

Digital printing machines, printing machine for boxes, with their flexibility, are suitable for various small batch printing scenarios. Whether it's personalized gift packaging, creative product packaging boxes, or small batch promotional materials and customized labels, digital printing can easily handle them. Taking e-commerce companies as an example, when launching new products or conducting promotional activities, they often require small quantities and diverse packaging and promotional materials. Digital printing precisely meets this fast and flexible demand.

Broad prospects

With the continuous growth of demand for personalized and customized products in the market, the scale of the small batch printing market continues to expand. Digital printing technology, as an ideal solution for small batch packaging printing, has extremely broad market prospects. More and more printing companies are introducing digital printing equipment to expand their business scope and enhance market competitiveness. It is expected that in the next few years, the market share of digital printing in the field of small batch printing will grow at a rate of 20% -30% per year.

The digital printing machine solution has demonstrated unparalleled advantages in cost, operation, production process, and application scenarios, making it an ideal choice for small batch packaging printing orders. It will lead the packaging printing industry towards a new stage of more efficient and flexible development.