Technology is constantly advancing, and Water based polymer carbon pigment ink is gradually demonstrating its unique advantages in the field of digital color box printing. Especially in the application of commonly used packaging materials such as copperplate paper and white cardboard, water-based carbon polymer pigment ink has brought new changes to the packaging color printing industry with its fast drying, efficient, and environmentally friendly characteristics.

1、 Industry application: Expand packaging color printing印

In the field of packaging color printing, art paper and white cardboard have always been the first choice for making packaging materials such as color boxes and cartons due to their excellent printing effect and durability. However, traditional printing inks often have problems such as slow drying speed and the need for additional drying equipment, which increases production costs and cycles. The emergence of water-based carbon polymer ink has perfectly solved these problems.

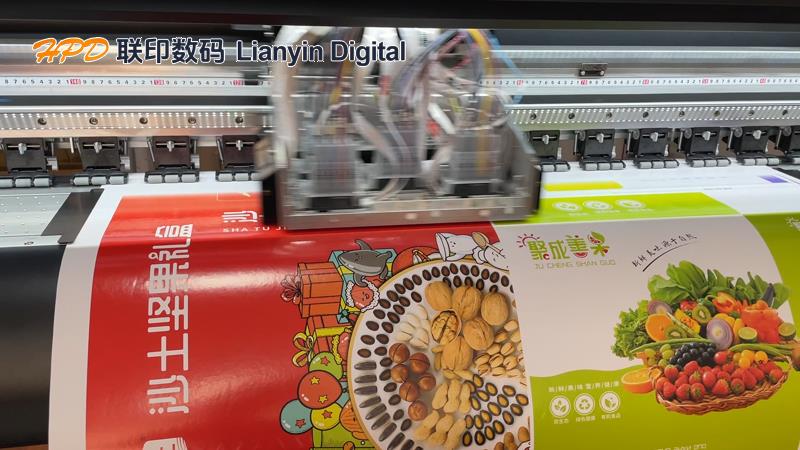

1. Small batch customized production: Water based polymer carbon pigment ink is suitable for digital printing machines without printing plates, and can achieve fast customized production of small batches and multiple varieties. This is undoubtedly a huge advantage for enterprises that need to frequently change packaging designs or conduct small-scale trial sales. No need for plate making, just import the design drawings and print directly, greatly shortening the production cycle and reducing inventory costs.

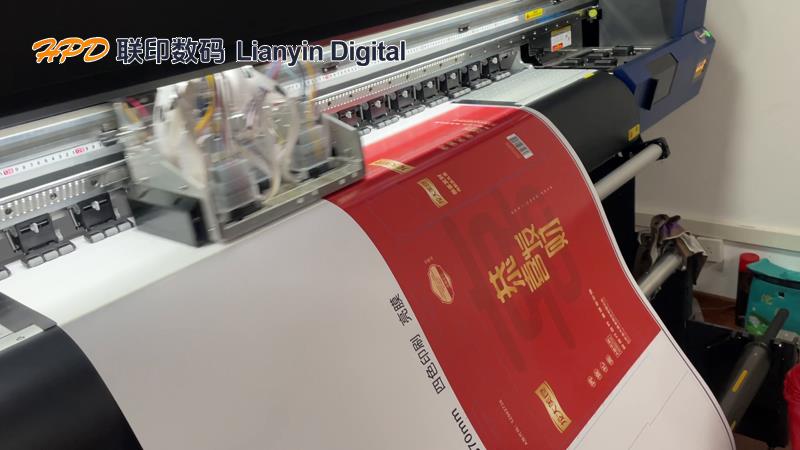

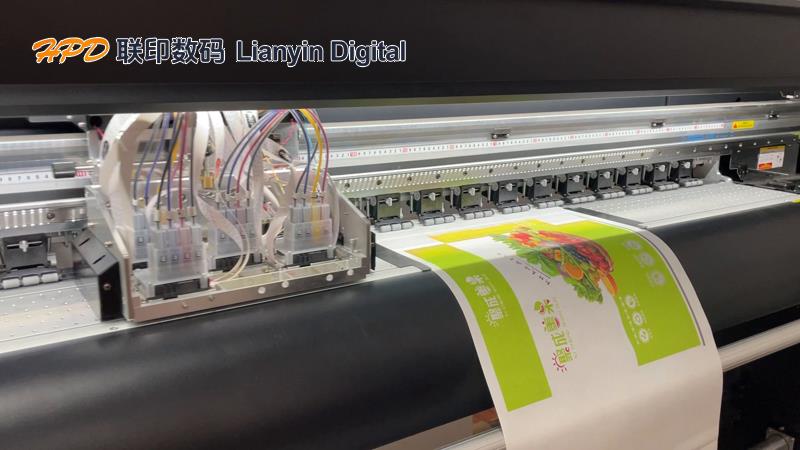

2. High quality printing effect: The printing effect of water-based carbon polymer ink on art paper and white cardboard is bright and delicate, with high color reproduction, which can meet the high requirements of the high-end packaging market for printing quality. Ink has strong permeability and adsorption strength, and the printed patterns are not easily peeled off, which increases the durability of the packaging.

3. Fast drying characteristics improve production efficiency: Water based polymer carbon pigment ink has fast drying characteristics, and digital printed packaging products can be quickly dried without the need for additional drying equipment, greatly improving production efficiency. This not only saves energy and time costs, but also makes the production of packaging products more flexible and able to adapt to the fast-paced market demand.

2、 Cost effectiveness: Reduce printing costs and enhance market competitiveness

1. Save drying equipment costs: Many adhesive type inks on the market require drying equipment to accelerate the drying process, which not only increases equipment investment costs but also consumes a large amount of energy. The fast drying characteristics of water-based carbon polymer ink make drying equipment unnecessary, thereby saving equipment costs and energy consumption.

2. Reduce consumable costs: Water based polymer carbon pigment ink has a relatively low ink consumption per square meter, and the nozzle has good moisturizing performance, reducing ink waste and nozzle maintenance costs. This is undoubtedly an important cost saving point for companies that require frequent replacement of packaging designs.

3. Improve production efficiency: The fast drying feature greatly shortens the production cycle of packaging products and improves production efficiency. Enterprises can respond to market demand faster, reduce inventory backlog, and enhance market competitiveness.

3、 Environmental advantages: practicing the concept of green printing and promoting sustainable development

Against the backdrop of increasing global environmental awareness, water-based carbon polymer ink, as an environmentally friendly ink, is gradually gaining favor in the market.

1. Non toxic and harmless: Water based polymer carbon pigment ink does not contain harmful substances such as volatile organic compounds (VOCs), and is harmless to human health and the environment. This makes the production of packaging products safer and more environmentally friendly, meeting the modern consumer demand for green products.

2. Recyclability: art paper and white cardboard, as commonly used packaging materials, have good recyclability. Packaging products printed with water-based carbon polymer ink will not cause secondary pollution to the environment during the recycling process, which helps to achieve resource recycling.

3. Reduce carbon emissions: The fast drying characteristics of Water based polymer carbon pigment ink eliminate the need for installing drying equipment, thereby reducing energy consumption and carbon emissions. This helps companies practice the concept of green printing and promote sustainable development.

With the continuous development of the packaging color printing market, this ink is gradually becoming the new favorite of the industry due to its fast drying, efficient, and environmentally friendly characteristics. It not only expands the infinite possibilities of packaging color printing, reduces printing costs, but also practices the concept of green printing and promotes sustainable development. In the future, with the continuous advancement of technology and the expansion of the market, it is believed that water-based carbon polymer ink will have a broader application prospect in the field of packaging color printing.