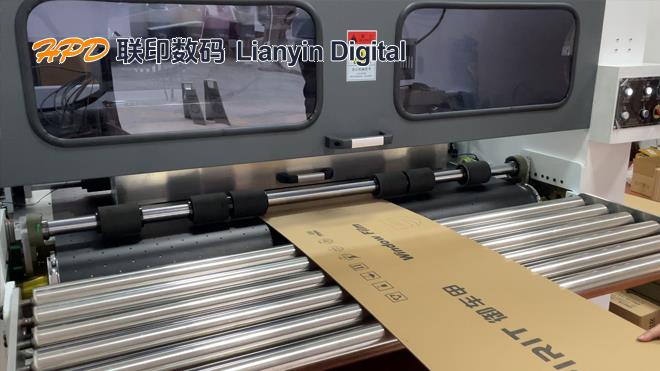

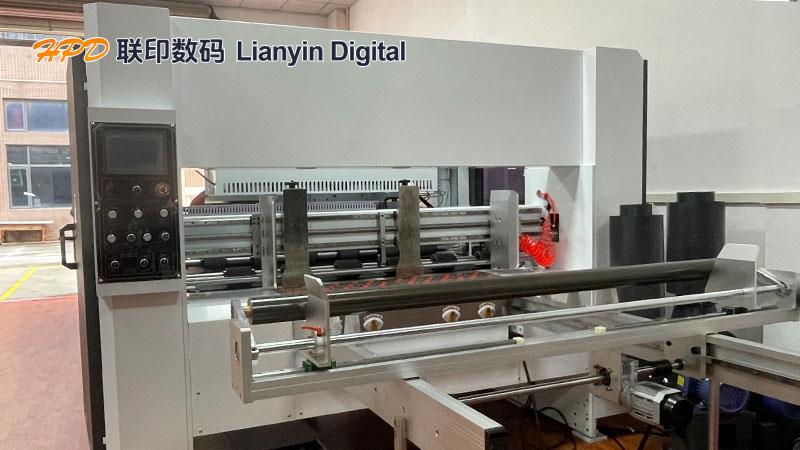

Integrated with advanced digital printing technology, the carton digital printing machine is designed specifically for personalized, small batch, and fast printing needs of cartons, cardboard, and other materials. It uses high-precision printing heads to directly print graphic and textual information onto the surface of cardboard boxes, without the need for traditional plate making processes, greatly shortening production cycles and reducing costs. Capable of meeting the market's demand for diversified and customized packaging. Its intelligent control system ensures stable paper feeding and precise positioning, suitable for the production of various specifications and materials of cardboard boxes, and is an important innovative tool in the modern packaging and printing industry.

Inaccurate paper feeding can lead to printing quality issues, so how can a cardboard digital printing machine ensure stable paper feeding? Today, Guangzhou Lianyin Digital, a manufacturer of corrugated digital printing machines, will briefly introduce how flat cardboard box printing machines achieve stable paper feeding through a series of designs and technical means. Here are some key measures:

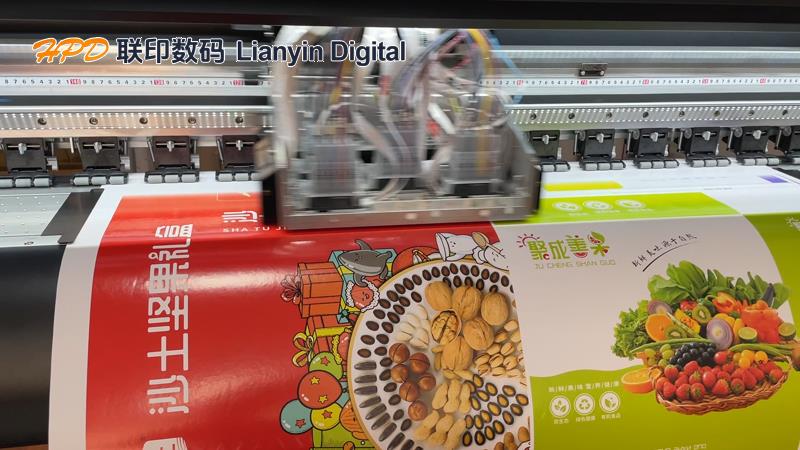

1、 Intelligent leading edge paper feeding system

Digital printing machines for cardboard boxes typically use an intelligent leading edge paper feeding system, which drives the paper to slide forward through one or more sets of paper feeding wheels. Although the leading edge paper feeding method may be slightly less stable than servo paper feeding, it has strong applicability and can be used for different materials and sizes of paper. It also has a fast paper feeding speed and is suitable for high-speed printing production lines. To ensure the stability of paper feeding, the leading edge paper feeding system may need to be combined with other technical means, such as tension control systems.

2、 Tension control system

The tension control system is an important guarantee for stable paper feeding in digital cardboard packaging printer. The system automatically adjusts the pressure and speed of the paper feeding wheel based on factors such as paper thickness, material, and printing speed to maintain a stable paper feeding state. By precise tension control, it is possible to ensure that the paper maintains the correct path and posture during transportation, preventing offset or curling, thereby improving printing quality and efficiency.

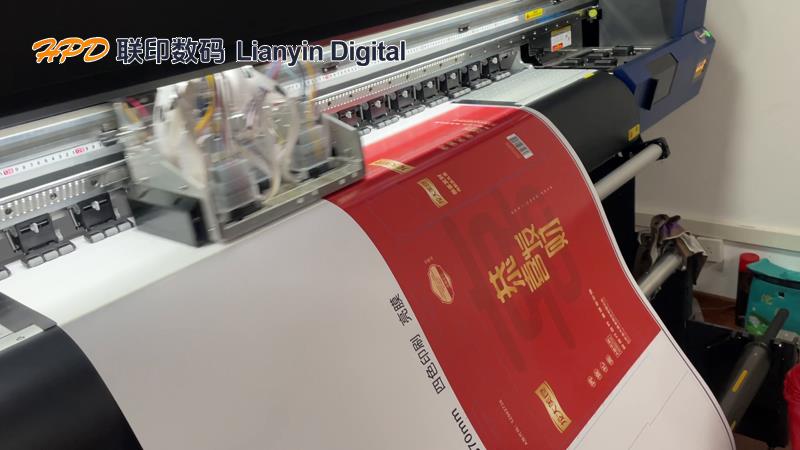

3、 Servo system motor

Servo system motor is a relatively advanced technology in modern printing production, and its high precision and stability provide strong support for the stable paper feeding of carton digital printing machines. The servo motor can accurately control the feeding and positioning of paper, and has a very precise control over the cardboard, with a control accuracy of up to 0.1mm. This high-precision control can ensure that there are no deviations or paper jams during the transportation process of the paper, thereby improving the accuracy and stability of printing.

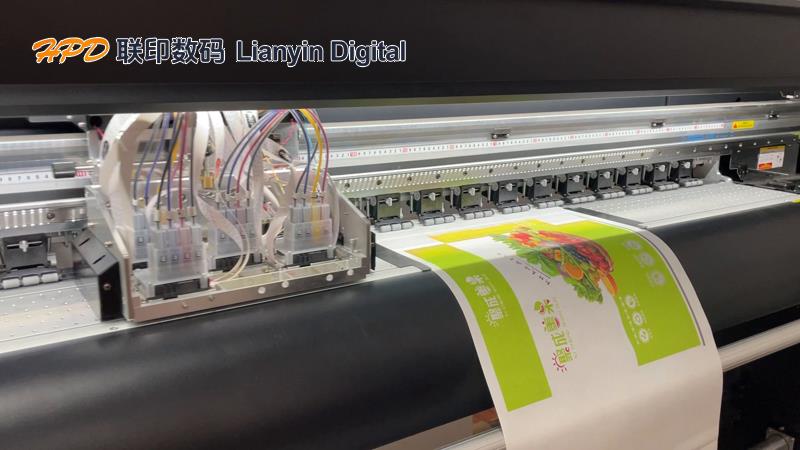

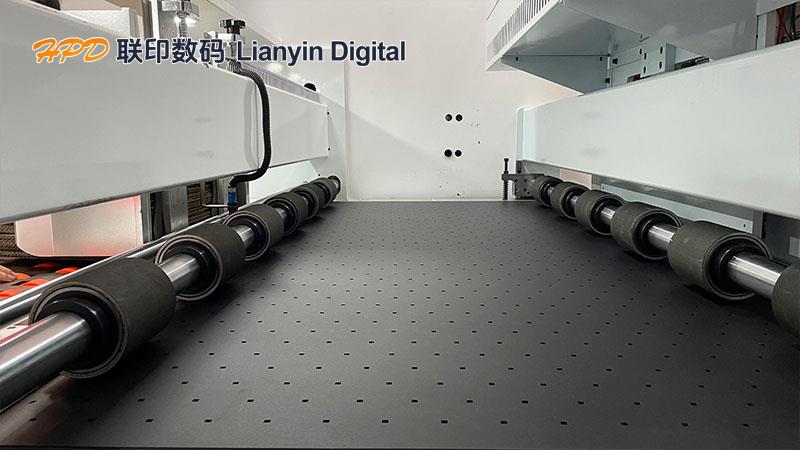

4、 Partition suction platform

The partitioned suction platform is another important component used in machines to stabilize paper. By controlling the suction force of the suction platform through zoning, it can ensure that the paper remains flat during transportation. This design can effectively prevent paper from deforming or curling due to uneven stress, thereby improving printing quality and efficiency.

5、 Operation and maintenance

Standardized operation: Operators need to follow safety operating procedures, understand the characteristics and basic performance of the machine, and adjust the printing paper feeding roller according to the thickness and material of the cardboard box to ensure smooth and accurate paper feeding.

Maintenance: Regularly maintain the machine, such as checking whether the electrical and mechanical systems are intact, and whether the printing rollers, mesh rollers, and other working conditions are good. Through effective maintenance, the service life of the machine can be extended and its stable paper feeding and efficient operation can be ensured.

In summary, the cardboard digital printing machine achieves stable paper feeding through intelligent leading edge paper feeding system, tension control system, servo system motor, partitioned suction platform, and standardized operation and maintenance measures. The organic combination of these technological means ensures the stability and reliability of the flat cardboard box printing machine in high-speed and high-quality printing.