In recent years, the rise of digital technology has profoundly changed the pattern of the packaging color printing industry, especially in the field of small batch customization. Digital printing technology has become an important supplement to traditional printing modes with its core advantage of "printing from one sheet without the need for plate making". Digital printing can quickly achieve customized and personalized design, meeting customers' diverse personalized needs while avoiding inventory backlog. This mode is particularly suitable for new product trial sales, holiday limited editions, and other scenarios. Enterprises can quickly test market reactions and reduce trial and error costs. Variable data in packaging traceability and product traceability can be easily printed using digital printing machines without templates.

Small batch customization allows brands to fully showcase their creativity and transform packaging into a carrier of brand stories. For example, a certain cosmetics brand launches co branded designer packaging every quarter, achieving high-precision color reproduction through digital printing. Fans compete to purchase in order to gather all styles, driving new products to sell out quickly. This' hunger marketing 'strategy has been efficiently implemented with the support of digital printing technology.

Traditional printing incurs fixed costs such as plate making fees and inventory fees, while digital printing produces on demand, significantly reducing capital occupation. For start-up brands or small and medium-sized enterprises, this model can ensure packaging aesthetics without affecting cash flow due to excessive investment.

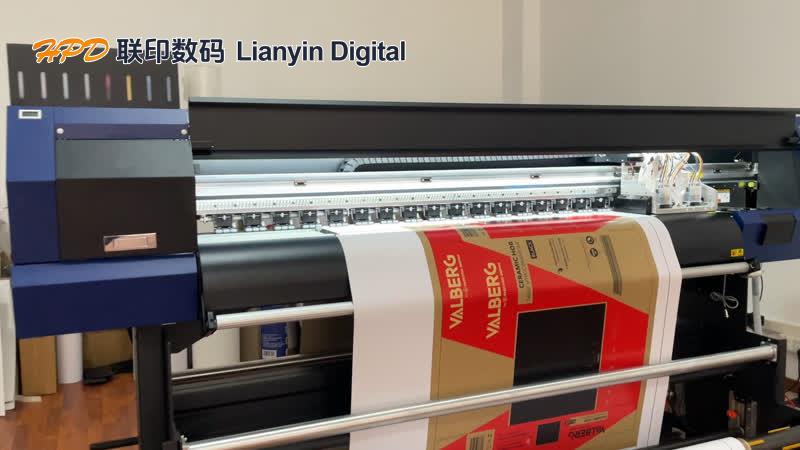

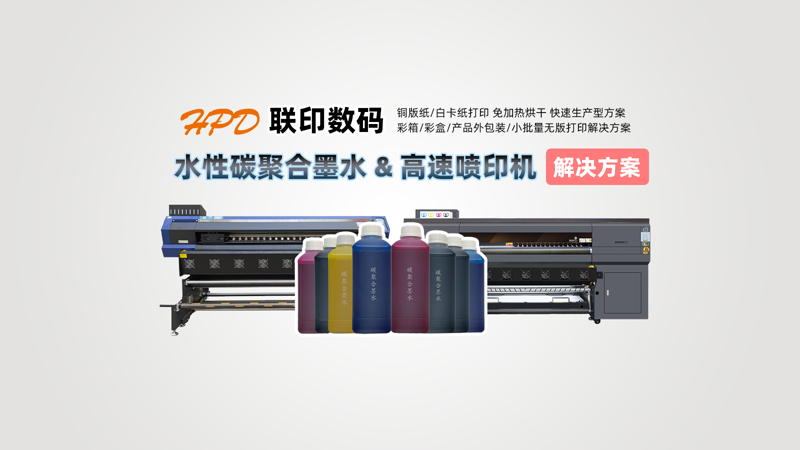

Of course, the development of digital packaging box printing technology will also face some challenges. For example, the cost of digital printing is relatively high, and comprehensive cost reduction can be achieved by optimizing digital printing machine equipment, ink consumables, and production processes. Guangzhou Lianyin Digital's small batch digital printing machine ink solution has a low ink consumption cost of 5 to 8 cents per square meter for full width printing, and can also print quickly without the need to turn on high-power external heaters, significantly reducing overall costs. Find a good packaging box printer solution, so you won't have to worry about high costs for color box orders.

In addition, there is production cycle pressure. Small batch orders often have tight deadlines and require quick delivery. To achieve good production through digital workflow, modular production, and optimized capacity allocation. Ensure timely delivery and customer repurchase.

Different materials have varying requirements for printing processes, and companies need to choose a technology combination based on product characteristics. If packaging boxes, color boxes, etc. require biodegradable materials and meet environmental standards, then water-based solutions are more suitable. UV printing is suitable for a wider range of media.

The packaging color printing small batch industry is currently in a golden development period driven by both technological innovation and market demand. Enterprises are based on technological innovation and guided by customer needs, building a "digital, intelligent, and green" industrial ecosystem. Based on the industry in which one operates, focus on niche areas such as alcohol packaging and customized design of agricultural products to form differentiated competitive advantages. Only in this way can we stand out in fierce market competition and achieve sustainable development.